Table of Contents

Culture media refers to the nutrient-rich substances used in laboratories to cultivate microorganisms such as bacteria and fungi. These substances, which may be liquid or solid, give the microbes with the required nutrients, minerals, and other elements for growth and reproduction.

In the late 19th century, when scientists first began to study microorganisms in depth, culture media came into being. Louis Pasteur, a French microbiologist, was one of the important figures in this discipline; he devised a range of culture media for growing different species of bacteria. This allowed him to examine the traits and activities of these microbes, which was essential for comprehending their role in sickness and other processes.

The significance of culture media lies in its capacity to facilitate the development and reproduction of microorganisms in regulated laboratory environments. This enables scientists to examine microorganisms in depth and gain an understanding of their traits, behaviours, and possible applications. Antibiotics, vaccines, and other biotechnology products are produced using culture media, for instance. Moreover, the study of microorganisms in culture medium is essential to the fields of medical and veterinary microbiology, agriculture and food safety, and environmental science.

What are the basic Components of Culture Media?

The fundamental elements of culture media are:

- Carbon source: This gives the microbes with the energy they need to develop and reproduce. Sugars such as glucose and fructose and organic acids such as lactic acid are examples.

- Nitrogen source: This offers the required building blocks for the synthesis of proteins and other nitrogen-containing molecules by microbes. Examples include ammonium salts, nitrates, and peptones.

- Trace elements and minerals: Minerals and trace elements are necessary for the growth and metabolism of microorganisms. Included are iron, zinc, and magnesium.

- pH buffer: This helps to maintain the pH of the culture medium within a specified range, which is required for the growth and metabolism of the majority of microorganisms.

- Agar or Gelatin: Agar and Gelatin are solidifying chemicals that make liquid culture media solid and are required for the cultivation of specific microorganisms.

- Growth factors: Certain microbes require growth nutrients, such as vitamins or amino acids, in order to grow and reproduce.

- Antimicrobials: Some culture medium contain antibiotics or other antimicrobials to hinder the growth of undesirable microbes or to select for resistant microorganisms.

- Inorganic salt: It delivers sodium, potassium, and calcium ions that assist maintain the osmotic balance of the medium and regulate the membrane potential of cultured cells.

- Buffering systems: It is necessary to maintain the optimal pH in cultures, which for most microbes is 7.0. In culture media, ammonia, calcium carbonate, and sodium hydroxide are frequent buffers. Primarily, the following buffering systems are utilised to attain the ideal pH:

- Natural buffering system: The system maintains a balance between gaseous CO2 and the CO3/HCO3 concentration of the culture medium. The technology is inexpensive and non-toxic, but it requires a controlled gaseous environment. Therefore, these cultures are nurtured in CO2 incubators with 5-10% CO2 in the air surrounding them.

- Red phenolic: It is typically found in culture media that is commercially distributed. It serves as a pH indicator and aids in monitoring the pH of the media. As microbial species proliferate in a medium, they emit specific metabolites that alter the pH of the medium. Therefore, if the medium contains phenol red, it will turn yellow at low pH, purple at high pH, and bright red at the optimal pH of 7.4. There are also other problems associated with the use of phenol red in culture media:

- Since phenol red mimics the action of steroids (particularly oestrogen), it should not be introduced to estrogen-sensitive cells (such as mammary tissue).

- Phenol red disrupts the sodium-potassium equilibrium of serum-free culture medium.

- The presence of phenol red hinders flow cytometric detection.

- HEPES (4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid): It is a buffer for zwitterionic sulfonic acid. It maintains a pH range of 7.2 to 7.4 in the medium and does not require a regulated gaseous environment. Nevertheless, the chemical is pricey and highly harmful to cultures.

- Amino Acids: These are the building blocks of proteins, a vital biomolecule for life that cultivated cells cannot produce on their own. They increase cell proliferation and cell density in cultures, particularly L-glutamine, a nitrogen source for cells that aids in the manufacture of NADP and NAD, which serve as a secondary energy source for developing cells. The amino acid should be introduced soon prior to utilising the medium, as it turns to cell-killing ammonia over time.

- Peptides and Proteins: They are required in serum-free media because serum, which includes fetuin, transferrin, albumin, aprotinin, and fibronectin, provides them in serum-containing media. Fibronectin, albumin, and transferrin are some of the most widely used proteins and peptides. These molecules serve an important role in culture media, eliminating harmful substances, transferring metabolites between cells and tissues, and suppressing serine proteases, among other functions.

- Vitamins: They are necessary for the growth and proliferation of cultured cells and organisms. In culture, serum is the primary source of vitamins; however, for some cell lines, other vitamins are supplied in place of serum. Vitamin B is the most frequent vitamin supplement.

- Fatty acids and lipids: They serve as carbon sources and offer energy for the growth and development of cultured cells or organisms. These biomolecules are supplied by serum in media containing serum, hence they are often added to media without serum.

- Media supplements: Certain cell lines need supplements such as growth factors, hormones, and signalling molecules in addition to the components of the medium and the serum. They assist cells and cultured organisms in growing, proliferating, and maintaining a proper metabolic rate. It is essential to evaluate the osmolality of the media after adding supplements, as they can negatively alter osmolality and inhibit cell growth. The optimal osmolality range for the majority of cell lines is between 260 and 320 mOSM/kg.

- Serum: It is a complicated mixture of growth inhibitors, growth factors, and albumin. It provides protein, amino acid, carbohydrate, vitamin, fat, trace element, growth factor, and mineral nutrients. In addition to shielding cells from mechanical harm, these molecules also serve as a buffer, increase cell adhesion to the substrate, and shield them from proteolysis. Normal serum concentrations in medium range between 1% and 10%.

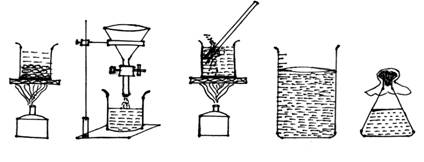

General Procedure of Culture Media Preparation

Materials/Equipment Requirement

- Pyrex flask (conical flask) at least double the size of the batch

- Magnetic Stir Bar

- Aluminum Foil

- Weighing machine

- Dehydrated culture media

- Spatula

- Graduated cylinder

- Distilled or deionized water

- Hot plate stirrer

- Autoclave

- Sterile Petri plates,

- Infrared no-touch thermometer

Step 1: Calculation and Weighing

Calculate and weigh the dehydrated medium in a dry atmosphere (low humidity), preferably beneath a laboratory fume hood. Ensure the table, balance, and supplies are dust- and powder-free and clean.

Balance

A top-loading (precision) balance is appropriate for weighing substances. Place the balance on a stable, level, and vibration-free table. Regularly (e.g., annually), calibrate the balance and verify the control weights before to usage.

Materials and PPE

While handling dehydrated media, a dust mask should be used to prevent inhalation of tiny particles. Use gloves to prevent direct skin contact. Wear safety eyewear (e.g., for sodium deoxycholate) when working with media containing irritants to the skin and eyes (read product instructions). Before and after dealing with dehydrated culture material, wash hands.

Calculate

Follow the directions of the manufacturer. Prepare a table containing the predetermined weights and volumes for a set number of plates. 20-25 mL are required to make a solid medium with a depth of 4 mm in a Petri plate with a 9 cm diameter. In a logbook, record the product’s name, lot number, preparation date, weight and volume of water, as well as the operator’s name.

Weighing

Utilize materials with a specified volume to enable weighing. Open the container and remove the necessary quantity of powder. Immediately seal the container to preserve its contents from dampness. Do not return the extra powder to the bottle.

Step 2: Mixing with Water and Heating

Typically, media powder must be dissolved by boiling, although the manufacturer’s instructions printed on media package inserts must be followed precisely. Utilize water that has been purified via distillation, deionization, or reverse osmosis. Copper ions, high conductivity, and a high pH can drastically alter the quality of media manufactured in-house. Because tap water alters selectivity and pH, it should not be used.

The quality of the glassware used for pouring media is also an essential consideration. Use borosilicate glass Erlenmeyers, bottles, and graduated cylinders to measure water and mix with media powder. If reusing glasses, only borosilicate glassware should be used, as soda glass can leach alkali into the medium and alter the pH of the medium, which may inhibit development.

Powder dissolving Procedure in water

- Add the pre-weighed powder to the flask after adding half of the required water. Preheating the water to 50 to 60 degrees Celsius may aid in dissolving.

- Stir or rotate briefly (do not shake!)

- Pour the remaining water down the edges of the flask to dissolve any powder clinging to the sides (dry powder may not be sterilised in the autoclave)

- Agar-containing media must be heated to dissolve. Do not tightly shut the flasks.

- With constant stirring, bring to a boil while heating until the solution becomes transparent.

- Avoid boiling, overheating, foaming, burning, clumping, and irregular mixing.

Step 3: Sterilization

The majority of media require sterilisation to ensure that only bacteria from patient specimens and not pollutants from water or powdered media will thrive. Some media cannot be autoclaved (e.g., SS agar, Cary Blair agar)

Before sterilisation, liquid media are dispersed to individual tubes or bottles. Autoclave a medium only after dissolving all of its constituents. Do not completely tighten the lids or caps. Before being placed in an autoclave, agar media are sterilised in big flasks or bottles sealed with plastic screw tops or plugs.

Autoclave sterilisation should begin as soon as the temperature hits 121°C and typically requires at least 15 minutes.

Ideal autoclaving volume is two litres. Autoclave performance must be monitored using sterilisation indications such as the Bowie Dick test and biological indicators such as Bacillus stearothermophilus spores.

Once the sterilising cycle is complete, the molten agar is cooled to around 50 degrees Celsius before being dispersed to individual Petri plates (approximately 20 to 25 mL of molten agar per plate).

Important

- Over-sterilization causes precipitation, pH shift, component degradation

- Insufficient sterilisation causes medium contamination.

- The covering permits steam permeation.

- There is sufficient room between the components for steam to circulate.

- To identify sterilised products, label the flask with indicator tape (medium name/code, date of preparation, initials).

- To verify autoclave cycles, use chemical indicators with each cycle (e.g., time-steam-temperature strips) and biological indicators at intervals.

- Use a “cool down programme” or wait until the pressure has dropped sufficiently (70-80°C) before opening to prevent a rapid pressure decrease (liquid can boil over, and caps can be blown off).

- Do not wait too long before removing the contents of the autoclave, as overheating may harm the media components.

Step 4: Fine-tuning (supplements and pH)

If other ingredients (such as sheep blood or specialised vitamins, nutrients, growth promoters, or antibiotics) are to be added, they should be included when the molten agar has cooled, just prior to plating.

The quality of the blood plays a crucial impact in the performance of blood-containing media; for instance, hemolytic reactions are easily differentiated in media containing sheep blood. Before blood is utilised for media preparation, its concentration, homogeneity, viscosity, and colour must be evaluated. For other additions, the certificate of analysis and sterility requirements should be examined.

Serum, some carbohydrate solutions, certain antibiotics, and other heat-sensitive compounds that cannot tolerate steam treatment by autoclaving must be sterilised individually by membrane filtering. Passage of solutions through membrane filters with pores ranging in size from 0.2 to 0.45 m in diameter does not remove viruses but removes the vast majority of bacterial and fungal pollutants.

Supplements Addition

- Allow the media to cool to 45-50°C before to adding heat. -labile supplements

- Filtrate and sterilise heat-sensitive supplements (not in the case of blood)

- Allow supplements to reach room temperature prior to addition. Add sterile supplements aseptically and ensure proper mixing.

Verification of pH after sterilization (not before)

- Before dispensing, use a pH metre to verify pH (typically at 25°C).

- Remove 20 mL from the flask, allow it to cool, and then measure the pH. Keep the flask in a water bath.

- Compare the pH to the range indicated by the manufacturer. If the pH is acceptable, continue administering.

- The pH of prepared dehydrated media should not need to be adjusted. In the event of a deviation, recheck the water, dehydrated medium, glassware, and method.

Dispensing of Prepared Culture Media

Before distributing, cool the culture media in a water bath (45-50°C) or hot plate stirrer to reduce condensation. The temperature can be determined using an infrared non-contact thermometer. Dispensing at a temperature that is too high causes significant evaporation. If media remain in a water bath for too long, precipitation may result (reheat, but do not overheat). Do not use cold water to chill down agar medium, since this may result in the production of flakes or clouds.

If using reusable glass Petri plates, sanitise them in a hot air oven at 160°C for two hours. Let the oven cool to 50 degrees Celsius before opening (to avoid cracking glassware). Distribute the media aseptically in a room with closed windows and without the use of fans or climate control. Work near a flame or within a biological safety cabinet.

Procedure for Agar media dispensing in plates

- Flame-sterilize the flask’s neck before to and between filling.

- Before dispensing, mix the culture media by gently spinning the flask.

- Dispense on a level surface

- The optimal agar depth for antimicrobial susceptibility testing is 4 0.5 mm: 90 mm diameter circular Petri plate: around 25 mL

- Utilize sterile, graduated pipettes or a syringe/pump for media distribution.

- Avoid creating air pockets (flame surface or use a heated loop to remove them).

Dispensing of agar or liquid media in tubes

- Use tubes with lids that allow for ventilation (such as screw caps), and do not entirely tighten.

- Put tubes in a rack that is autoclavable.

- Gently blend by rotating the flask prior to dispensing.

- Dispense the appropriate amount per tube. Utilize sterile, graduated pipettes or a syringe/pump for media distribution.

- After autoclaving, secure screw caps firmly

Drying of plates/tubes

- Dry at room temperature for several hours (up to 24 hours) to remove condensation.

- Less than 30 minutes with the lid slightly ajar. If there is a possibility of contamination, keep lids closed.

- Dry the lids before packing to prevent moisture. Avoid over-drying (cracks).

- The rate of drying depends on the medium:

- Allow agar slants to dry in a slanted position to create a 2.5-3 cm deep butt and a 2-2.5 cm long slope. Utilize a validated and standardised rack.

- Dry on a rack agar, semi-solid tubes, and liquid medium (vertical position).

Preparation of Common media and cultures

Culture media

The procedure for preparing fundamental microbiology media is provided below. Liquid and solid media that have been prepared and sterilised are available from the major providers of classroom science equipment for instances in which preparation would be inefficient. 15 minutes are spent at 121 °C (15 lb/in -2) to ensure sterility. pH readings are 7.0 unless otherwise specified.

Allow 15 cm3 of agar per Petri dish and 5-10 cm3 of broth every McCartney bottle as a note. All cotton wool plugs should be produced from cotton wool that is not absorbent. Metal or plastic caps may also be used.

Nutrient agar

- Mix 28 grammes of nutritional agar powder with one litre of purified water. Bring to a boil to completely dissolve. Dispense and sterilise as needed.

Nutrient broth

- Mix 13 grammes of nutritional broth powder with one litre of purified water. Blend well. Dispense and sterilise as needed.

Malt extract agar

- Mix 18 grammes of agar powder with one litre of distilled water. Bring to a boil to completely dissolve. Add 15g malt extract per litre. Blend well. Dispense and sterilise as needed.

Mannitol yeast extract agar

- Suspend 10 grammes of agar in one litre of purified water. Heat in order to dissolve. Add 0.5 grammes of K2HPO4, 0.2 grammes of MgSO4.7H2O, 0.2 grammes of NaCl, 0.2 grammes of CaCl2.6H2O, 10 grammes of mannitol, and 0.4 grammes of yeast extract. Dispense and sterilise as needed.

Mannitol yeast extract broth

- As above, without agar.

Glucose nutrient broth

- Prepare nutritional broth as indicated and add 10 grammes of glucose per litre.

Sugar peptone water

- The pH should be 7.4 after adding 10 g of peptone, 5 g of NaCl, 5 g of sugar, and 20 cm3 of Universal indicator to 1 litre of distilled water. Dispense and sterilise as needed.

Tributyrin agar

- Supplied in a usable state. Melt by heating and distribute aseptically. Obtainable by combining 1% tributyrin with nutritional agar.

Glucose yeast extract broth

- Add 10 grammes of peptone, 5 grammes of sodium chloride, and 3 grammes of yeast extract to one litre of distilled water. Dispense and sterilise as needed.

Glucose yeast extract lemco broth

- Add 10 g of Lemco (meat extract) to the broth made from glucose yeast extract.

Milk agar

- Prepare nutrient agar as described above, but use 900 cm3 of pure water. Dissolve 20 g of dry skimmed milk in 100 cm³ of purified water. Sterilize independently. After the milk has cooled to between 45 and 50 degrees Celsius, transfer it to the agar in an aseptic manner. Distribute aseptically

Starch agar

- Suspend 15 grammes of nutritional agar in 100 millilitres of purified water. Bring to a boil to completely dissolve. For a suspension, heat 40 grammes of soluble starch in 100 millilitres of purified water. Cool, then combine with the nutrient agar solution. Dispense and sterilise.

Iodine solution

Dissolve 1 gramme of iodine crystals and 2 grammes of potassium iodine dissolved in 300 millilitres of purified water.

Cellulose broth (for Trichoderma reesei)

- 800 cm3 distilled water

- 0.1 g CaCl2

- 0.5 g (NH4)2SO4

- 0.5 g yeast extract powder

- 0.5 g asparagine

- 10 g carboxymethylcellulose

- 1.0 g KH2PO4

- pH6.2

Combine ingredients, heat on a low flame, and whisk until dissolved.

Maintenance and Preservation of Cultures

Cells are grown in a culture medium until they are used in tests; however, when they must be maintained and stored for future research, additional chemicals are added. The four ways currently accessible for keeping and maintaining cultures for future research are as follows:

1. Refrigeration

- In this method, bacterial cultures are preserved in refrigerators or cold storage at 4 degrees Celsius. Under these conditions, the metabolic process of the cells is slowed, allowing for a slower use of the supplied medium. In addition, the procedure shields cultures against deterioration caused by medium evaporation and aids in their long-term preservation.

- However, the approach has its limitations: when the cells consume the medium, they release waste products that might accumulate in the vessel and induce cell death. The solution to this issue is subculturing cells or microbes for a predetermined period of time. For instance, bacterial species must be subcultured for two to three weeks, whereas fungal species must be subcultured for three to four months.

2. Deep Freezing

- In this approach, cultures are preserved in glycerol and stored in a deep freezer at -40oC for several years. On the agar slope, 2ml of glycerol is added and agitated to create a suspension of cultures.

- The suspension is then put into an ampoule (a storage vial) containing a mixture of industrial methylated spirit and carbon dioxide, and promptly frozen at -70 degrees Celsius. They are then removed from the -70°C freezer and the mixture of methylated alcohol and carbon dioxide, and placed in a -40°C freezer.

- Before using the suspension cultures for experiments, they are removed from the freezer and placed in a water bath until the suspension melts and can be used to make a streak plate.

3. Freezing Under Liquid Nitrogen

- In this technique, cells or microorganisms are kept at -196oC in liquid nitrogen. It halts the metabolic activities of cells, allowing them to survive unmodified for an extended period of time.

- To prevent the creation of ice crystals that can kill the cells, they are suspended in glycerol or DMSO (dimethyl sulfoxide) and stored in liquid nitrogen in an ampoule. For cells that cannot be preserved with lyophilization, this procedure is preferred.

4. Lyophilization or Freeze Drying

- In this technique, cultures are rapidly frozen at -70 degrees Celsius and subsequently dehydrated under vacuum. The frozen-dried cultures are then vacuum-sealed and stored in the dark at a temperature of 4 degrees Celsius.

- It is the best approach in laboratories for long-term preservation of cultures, including bacteria, fungi, and viruses. During use, cultures are revitalised by adding liquid media to the vial and then transferring it to an appropriate growth/culture medium.

Examples of Culture Media Preparation

Nutrient Broth (NB) and Nutrient Agar (NA)

- To assist prevent the infection of your media, wipe off the lab bench with disinfectant.

- In a 1 L graduated cylinder, measure about 250 ml of distilled water (placed in a 60°C water bath) and transfer to a 1 L flask.

- Add 1.5 g of beef extract and 2.5 g of peptone to the flask. Wash and dry the spatula between bottles. DO NOT return weighed-out surplus material to the container; trash. Use around 100 ml of the water to rinse any powder that has adhered to the edge of the flask into the mixture.

- Stir thoroughly over a bunsen burner’s low heat to dissolve entirely. Pour the mixture into the 1 L graduated cylinder and fill to the 500 ml mark with warm water. Return the liquid to the flask.

- Check the pH of the medium and, if necessary, adjust it to 7.0 with HCl and/or NaOH. The addition of agar in the subsequent stage will not significantly alter the pH.

- Inject 10 ml of the mixture into each test tube using a pipette. Construct ten tubes and arrange them in a test tube rack.

- Add 6.0 grammes of agar to the flask and label it “Not Applicable.” Bring to a boil for 1 to 2 minutes while stirring continuously. The agar will not dissolve unless it is boiled; after it has dissolved, the fluid will become fully transparent. Pipette 10 ml of cooled agar into tubes after allowing it to cool to the point where there is no danger of getting burned. Make ten 10 ml tubes.

- Closing the flask with a Styrofoam plug wrapped in cheesecloth and secured with tape. Use a second piece of tape to wrap around the flask’s neck and pass over the first piece. All of the tubes are sealed with Morton caps. These must be entirely depressed, or they will be expelled during the autoclave’s exhaust cycle. They continue to self-vent even when pushed all the way down.

- To demonstrate the necessity for sterilisation, store one of each type of tube in a drawer until the following class. Observe development for one more period.

- Autoclave the flask and tubes in the slow exhaust mode for 15 minutes at 121 °C and 15 lb/in2 pressure. Observe how your instructor uses the autoclave.

- After removing the media from the autoclave, chill and preserve the broth tubes for future use. Place the flask in the water bath at 48°C. Place the tubes of NA quickly on the slant racks on the middle table so that the medium forms a long slant and a short butt, and allow them to harden. The agar should not reach the top of the tube. Allow them to completely cool before placing them back on the rack. Store for later use. Label holder.

- Place your petri dishes on the seat of the bench. The cover must be placed on top. Then, remove the flask from the water bath and ignite the Bunsen burner. To prevent the leaking water from infecting the plates, thoroughly dry the base.

- The cotton stopper and tapes must be removed from the flask. Carefully ignite the flask’s neck, then open the plate cover halfway and fill the plate halfway. The plates have a full line on the side; fill to or slightly above that line. Put in slightly too much as opposed to too little. If the medium in the plate is insufficient, it will dry out in the incubator.

- Burn the flask’s neck between each plate. Each student is required to fill at least two plates. Rinse the extra agar out of the flask IMMEDIATELY with hot tap water and leave on the waste cart. It will take 15 minutes for the plates to harden entirely. Then, invert, label, and incubate at 37 °C overnight to evaporate excess moisture and examine for microbial contamination.

- Clean all glasses and place them on paper towels next to the sink.

Potato dextrose agar (PDA) Preparation

Medium consisting of potato dextrose and agar is often used for isolating fungi and maintaining them.

- Wash and peel 250 grammes of potato before slicing it into little pieces.

- Cook the potato slices in 500 ml of water for 30 minutes in an open pot or pressure cooker.

- Combine 20 grammes of agar with 500 millilitres of water and boil for 30 minutes.

- Filter the potato extract through a muslin cloth or a net filter to collect it.

- Combine 20 grammes of dextrose with potato extract

- Mix the molten agar with the potato-agar mixture completely, and adjust the volume to 1 litre with purified water.

- Using pH sheets, measure the pH of the medium.

- Pour 15 ml of the medium into each clean boiling tube and plug with non-absorbent cotton wool.

- Place the tubes in a wire basket, cover it with a sheet of waste paper, and secure with a cotton thread.

- 20 minutes in an autoclave or a pressure cooker with 15 pounds of pressure.

- After releasing the steam, remove the sterilised tubes and place them in a slanted position to create agar slants.

- The tubes are stacked in a wire basket and stored in a clean environment once they have solidified.

Method for measuring pH: Stir the medium with a glass rod, then dip a small piece of pH indicator paper into the media. Take it out and compare the colour development to the colour chart provided on the filter paper book’s cover sheet. If the pH is greater than seven, add a few drops of 0.1N hydrochloric acid (HCl), stir thoroughly, and retest for neutrality. If the pH of the medium is less than 7, add a few drops of 0.1 N sodium hydroxide (NaOH) to raise it to 7.

Some of the commonly used media

Potato dextrose agar (PDA)

| Potato | 250 g |

| Dextrose | 20 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Oatmeal agar (OA)

| Oatmeal | 30 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Wheat meal agar (WMA)

| Wheat grain | 30 g |

| Agar agar | 30 g |

| Distilled water | 1000 ml. (pH : 7) |

Malt extract agar (MEA)

| Malt extract | 25 g |

| Agar agar | 20 g |

| Distilled water | 1000 ml. (pH : 7) |

Yeast potato dextrose agar (YPDA)

| Yeast granules | 1 g |

| Potato | 200 g |

| Dextrose | 20 g |

| Agar agar | 20 g |

| Distilled water | 1000ml (pH: 7) |

Most Common Errors and Possible Causes during Culture Media Preparation

1. Clumping of dehydrated culture media

- excessive humidity during storage

- The container was left open for an extended period of time or was not closed securely after use.

- Dehydrated culture media past its expiration date

2. Wrong pH

- The pH metre has not been calibrated.

- Verification of pH was conducted on a medium that was excessively hot (normally 25°C).

- Utilization of inferior water or containers

- Utilization of chemically tainted containers Unfinished dissolution/mixing of medium

- Dehydrated medium improperly stored (e.g., not firmly sealed) or beyond its expiration date

3. Incomplete solubility

- Use of insufficient water

- Insufficient heating or time for dissolution

- Inadequate soaking or inadequate mixing

- Too-small flask to permit enough mixing and/or convection

4. Incomplete gelling or soft agar

- Incorrect product-to-water ratio: weighing error or overdilution Agar not adequately dissolved: bad mixing Extended storage at 50 degrees

- Possible overheating of culture media at low pH

- Remelting repeatedly causes overheating.

5. Darkening, caramelization

- Overheating: excessive sterilisation, heterogeneous mixing media maintained at 50°C for too long, frequent re-melting, or excessively high temperature.

- Medium dissolution incomplete

6. Turbidity, precipitation

- Substandard dehydrated media

- Use of inferior water or containers

- Overheating: excessive sterilisation, heterogeneous mixing media maintained at 50°C for too long, frequent re-melting, or excessively high temperature.

- Wrong pH

- Unfinished dissolution/mixing of medium

- Due to evaporation, the prepared culture medium loses water.

7. Poor growth or loss of differential properties

- Utilization of incorrect or inadequately maintained QC organisms

- Overheating: excessive sterilisation, heterogeneous mixing media maintained at 50°C for too long, frequent re-melting, or at an excessively high temperature

- Unfinished dissolution/mixing of medium

- Inhibiting components in water, container, or inoculum. Wrong PH

MCQ on Culture Media

1. What is the primary purpose of culture media?

a) To provide nutrients for microorganisms

b) To sterilize microorganisms

c) To inhibit the growth of microorganisms

d) To differentiate between different types of microorganisms

2. What is the most common method of sterilizing culture media?

a) Filtration

b) Chemical sterilization

c) Autoclaving

d) Incineration

3. What type of culture media is best for growing bacteria?

a) Solid (agar-based)

b) Liquid

c) Semisolid

d) Both A and C

4. What is the ideal storage condition for culture media?

a) Room temperature

b) Warm and humid

c) Cool and dark

d) Cold and dry

FAQ

What is culture media and why is it important?

Culture media is a nutrient-rich solution used to grow microorganisms, such as bacteria and fungi. It is important because it provides the necessary nutrients for the microorganisms to grow and multiply.

What are the different types of culture media?

There are many different types of culture media, including: solid (agar-based), liquid, and semisolid. Each type of media is formulated to support the growth of a specific type of microorganism.

How do you prepare culture media?

Culture media is typically prepared by mixing a dehydrated powder with water and sterilizing the mixture by autoclaving. Some media can also be purchased ready-to-use.

How do you sterilize culture media?

Culture media is typically sterilized by autoclaving, which uses high pressure and temperature to kill any microorganisms present. Other methods of sterilization include filtration and chemical sterilization.

How do you store culture media?

Culture media should be stored in a cool, dark place to preserve its nutrient content. Once opened, it should be used as soon as possible or stored in a refrigerated environment.

How do you select the appropriate culture media for your microorganism?

The appropriate culture media for a microorganism depends on its growth requirements. Factors to consider include pH, temperature, oxygen requirements, and the presence of specific nutrients.

What is the difference between selective and differential culture media?

Selective culture media is formulated to favor the growth of a specific type of microorganism, while inhibit the growth of others. Differential culture media is formulated to differentiate between different types of microorganisms based on their growth patterns or metabolic by-products.

Can culture media be reused?

Culture media should not be reused as it can lead to contamination with other microorganisms and also decrease the nutrient level.

Can you use tap water to prepare culture media?

Tap water should not be used to prepare culture media as it may contain microorganisms and other contaminants. Instead, it is recommended to use distilled or sterile water.

Can you add antibiotics to culture media?

Yes, antibiotics can be added to culture media to inhibit the growth of unwanted microorganisms or to select for specific microorganisms that are resistant to the antibiotic. However, it should be done under the guidance of a professional and in compliance with the local regulations.

References

- https://www.sigmaaldrich.com/IN/en/applications/microbiological-testing/microbial-culture-media-preparation

- https://www.mt.com/in/en/home/applications/Laboratory_weighing/Culture-Media-Preparation.html

- https://www.rpcau.ac.in/wp-content/uploads/2020/03/Media-and-their-composition.pdf

- https://www.thermofisher.com/blog/food/five-tips-for-culture-media-preparation-success/

- https://www.sigmaaldrich.com/IN/en/applications/cell-culture-and-cell-culture-analysis/cell-culture-by-technique/cell-culture-media-preparation

- http://www.cabri.org/guidelines/micro-organisms/M203Ap1.html

- https://www.sas.upenn.edu/LabManuals/biol275/Table_of_Contents_files/2-PreparationOfMedia.pdf

- https://agritech.tnau.ac.in/farm_enterprises/Farm%20enterprises_%20Mushroom_Culture%20media.html

- https://labassociates.com/how-to-prepare-culture-media-for-plant-tissue-culture

- https://conductscience.com/how-to-prepare-culture-media-and-preserve-cultures/

- https://microbiologyonline.org/teachers/preparation-of-media-and-cultures

- https://microbeonline.com/preparation-of-culture-media/

hi thank you very much