Table of Contents

Incubator definition

An incubator is an insulated and enclosed device used in biological laboratories. It creates an optimum environment which is required for the growth of microorganisms by providing optimum temperature, humidity, and other environmental conditions such as the CO2 and oxygen content inside’s atmosphere.

In laboratories, it is used to grow and maintain microbiological cultures or cell cultures. Both bacterial and eukaryotic cell organisms are cultivated by using an incubator.

Working Principle of Incubator

All incubators work based on a simple principle that microorganisms require an optimum environment for their growth and development. An incubator provides an optimum level of temperature, humidity, oxygen, and carbon dioxide so that the microorganism can multiply and increase their numbers.

Incubator contain a thermostat which maintains the inside temperature of the incubator. We can monitor this temperature from the outside via the thermometer. By utilizing the heating and no-heating cycles we maintain the inside temperature of the incubator.

In heating cycle, the thermostat increases the temperature of incubator whereas in the non-heating cycle the incubator is cooled by radiating heat to the surrounding. The cabinet contains an insulation system that separates it from the outside and allows the microbes to grow effectively.

Similarly, the incubator also maintains the other parameters such as humidity, airflow, co2 concentration, pH, through different mechanisms which are required for the growth of the organisms.

Some incubators also contain a shaker or aeration device which continuously shake the culture for cell aeration and solubility studies.

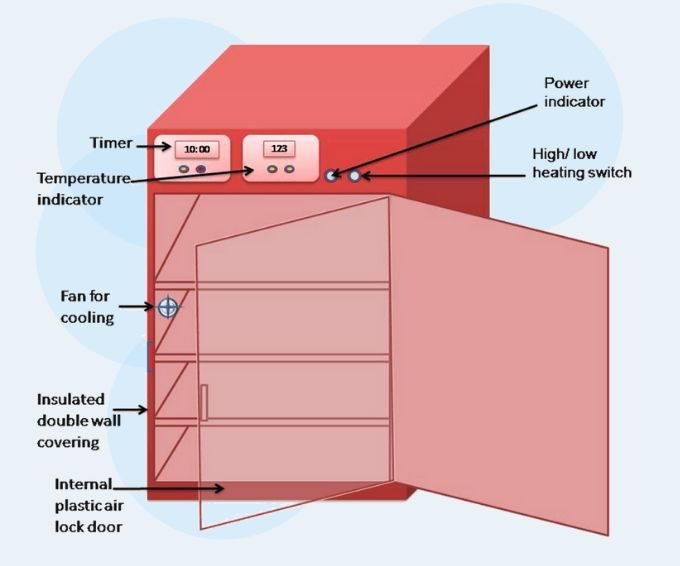

Components of an Incubator

An incubator is made up of different parts or components which help to maintain the optimum condition required for the bacteria growth. The parts of an incubator are;

(i) Cabinet

- The cabinet is made of a double-walled cuboidal enclosure. It has a capacity of 20 to 800L.

- It consists of an inner wall which is made of aluminum and an outer wall which is made of stainless steel sheets.

- To provide insulation to the incubator the inner gap between the inner wall and outer wall is filled with glass wool. It prevents heat loss from the incubator.

(ii) Door

- The incubator contains an insulated door that encloses the insulated cabinet.

- There also presents a glass door that enables the visualization of the interior of the incubator.

(iii) Control Panel

- It is located at the outer of the incubator. It consists of many switches and indicators which monitor the different parameters of the incubator.

- It also controlled the thermostat device.

(iv) Thermostat

- It is used to achieve the desired temperature within the incubator.

- It constantly maintains the specified temperature within the incubator by the heating and no-heating cycles.

(v) Perforated shelves

- It is located on the inner wall of the incubator. The plates of culture media are placed over it.

- These shelves are removed, which means we can clean them properly.

- The shelves contain perforations which help in the movement of hot air throughout the inside of the incubator.

(vi) Asbestos door gasket

- It provides an airtight seal between the door and the cabinet.

- It separates the hot environment of the cabinet from the external environment and prevents the outside air from entering the cabinet.

(vii) L-shaped thermometer

- It is located on the top part of the outer wall of the incubator.

- One end of this thermometer contains gradations which indicate the inside temperature of the incubator.

- Another end of this thermometer contains a mercury bulb which is located within the incubator.

(viii) HEPA filters

- Some incubators also contain HEPA filters, it helps to reduce the contamination which is created by the airflow.

- It is connected with an air-pump which circulates the air within the incubator so it creates a closed-loop system to reduce the chances of contamination.

(ix) Humidity and gas control

- A water source or reservoir is located underneath the chamber. This water is vaporized to control the relative humidity inside the incubator.

- It also contains a gas chamber that maintains the CO2 concentration within the incubator.

Types of Incubator in laboratory

There are different types of incubators in microbiology. These are classified based on the types of parameters or the purpose of the incubator.

1. Benchtop incubators

- Most of the laboratories contain Benchtop incubators. It has a basic function of temperature control and insulation.

- Temperatures range from ambient to 100 degrees Celsius. The majority of these incubators have a glass door, alarms, and a screen that indicates the time and temperature.

Benchtop incubators advantage and disadvantage

Here are some advantages of benchtop incubators:

- Compact size: Benchtop incubators are small and compact, which makes them a convenient and space-efficient option for laboratories and other research facilities.

- Wide range of applications: Benchtop incubators are available in a variety of sizes and models, with different features and capabilities. This makes them suitable for a wide range of applications, such as growing or culturing cells, microorganisms, or plants.

- Easy to use: Benchtop incubators are relatively easy to use, with intuitive controls and simple maintenance requirements.

- Energy-efficient: Benchtop incubators use less energy than larger incubators, which can save you money on energy costs and reduce your carbon footprint.

Here are some potential disadvantages of benchtop incubators:

- Limited capacity: Benchtop incubators are smaller than other types of incubators, which means they have a limited capacity. This may not be suitable for large-scale applications or for growing or culturing large quantities of cells, microorganisms, or plants.

- Limited temperature range: Some benchtop incubators may be limited in terms of the temperature range they can maintain, which may be a disadvantage for certain applications.

- May not have advanced features: Benchtop incubators may not have all the advanced features and capabilities of larger incubators, such as precise temperature control or the ability to control gas concentrations.

Overall, benchtop incubators are a convenient and space-efficient option for laboratories and other research facilities that need to maintain a controlled environment for growing or culturing cells, microorganisms, or plants. They are available in a variety of sizes and models, with different features and capabilities to suit different needs and applications. However, they may have some limitations, such as a limited capacity and a limited temperature range, which may be a disadvantage for certain applications.

2. Shaker incubator

- It contains a shaker which continuously shakes the culture media for proper aeration. It transfers the heat uniformly within the incubator.

- A shaking incubator is a motor/shaker paired with an incubator. The incubator has temperature, humidity, and oxygen levels under control.

- Similar to a centrifuge, it provides continual shaking for an uniform combination of the samples. It is utilised mostly in molecular biology and genetics.

Shaker incubator advantages and Disadvantages

Here are some advantages of shaker incubators:

- Controlled environment: Shaker incubators allow you to maintain a consistent, controlled environment for growing or culturing cells, microorganisms, or plants. This is particularly useful for studying the growth and behavior of cells, microorganisms, or plants under different conditions.

- Shaking motion: Shaker incubators provide a shaking motion that can be useful for a variety of applications, such as mixing or homogenizing cultures, aerating cultures, or simulating physiological conditions.

- Wide temperature range: Many shaker incubators are designed to operate over a wide temperature range, from below freezing to room temperature. This allows you to study the growth and behavior of cells, microorganisms, or plants under a variety of temperature conditions.

- Compact size: Shaker incubators are typically smaller and more compact than other types of incubators, which makes them a convenient and space-efficient option for laboratories and other research facilities.

- Easy to use: Shaker incubators are relatively easy to use, with intuitive controls and simple maintenance requirements.

Here are some potential disadvantages of shaker incubators:

- Limited temperature range: While many shaker incubators are designed to operate over a wide temperature range, they may not be suitable for all temperature ranges. For example, some models may not be able to maintain temperatures below freezing, which could be a disadvantage for certain applications.

- More expensive: Shaker incubators may be more expensive to purchase and operate compared to other types of incubators, especially for larger models or those with advanced features.

- Requires a stable power source: Shaker incubators rely on a consistent power supply to maintain a stable temperature and shaking motion. Any power outages or fluctuations can affect the temperature and shaking in the incubator, which can be detrimental

3. CO2 incubators

- This type of incubator automatically controls the CO2 and humidity within the chamber.

- Some microbes cannot develop in environments where oxygen is present. The CO2 incubator offers this atmosphere.

- It includes a unique system that helps maintain CO2 within the incubator’s chamber. Typically, infrared or thermal conductivity sensors measure CO2 concentration.

- Additionally, a water dish is included for controlling humidity levels.

- The incubator simulates the conditions that render the human body susceptible to contamination. Therefore, there is a specialised sterilisation system that cleans and prevents contamination of the incubation chamber.

- This sort of incubator is utilised for the growing of various bacteria requiring a CO2 concentration of 5-10%.

- For humidity regulation, water is stored beneath the incubator’s cabinet.

CO2 incubators Advantages

CO2 incubators are specialized pieces of laboratory equipment used to maintain a controlled environment for growing or culturing cells, microorganisms, or plants. They are commonly used in research laboratories and other scientific settings to study the growth and behavior of cells, microorganisms, or plants under different conditions.

There are several advantages to using CO2 incubators:

- Controlled environment: CO2 incubators allow you to maintain a consistent, controlled environment for growing or culturing cells, microorganisms, or plants. This is particularly useful for studying the growth and behavior of cells, microorganisms, or plants under different conditions.

- Wide temperature range: Many CO2 incubators are designed to operate over a wide temperature range, from below freezing to room temperature. This allows you to study the growth and behavior of cells, microorganisms, or plants under a variety of temperature conditions.

- Controlled CO2 levels: CO2 incubators are equipped with a gas delivery system that allows you to control the concentration of CO2 in the incubator. This is useful for studying the effect of different CO2 levels on the growth and behavior of cells, microorganisms, or plants.

- Energy-efficient: CO2 incubators use less energy than other types of incubators, which can save you money on energy costs and reduce your carbon footprint.

- Compact size: CO2 incubators are typically smaller and more compact than other types of incubators, which makes them a convenient and space-efficient option for laboratories and other research facilities.

Overall, CO2 incubators are a useful tool for growing or culturing cells, microorganisms, or plants under controlled conditions. They offer a wide range of temperature options and allow you to control the concentration of CO2, making them a convenient and practical choice for many research applications.

CO2 incubators Disadvantages

While CO2 incubators offer several advantages, there are also a few potential disadvantages to consider:

- Limited temperature range: While many CO2 incubators are designed to operate over a wide temperature range, they may not be suitable for all temperature ranges. For example, some models may not be able to maintain temperatures below freezing, which could be a disadvantage for certain applications.

- More expensive: CO2 incubators may be more expensive to purchase and operate compared to other types of incubators, especially for larger models or those with advanced features.

- Requires a stable power source: CO2 incubators rely on a consistent power supply to maintain a stable temperature and CO2 concentration. Any power outages or fluctuations can affect the temperature and CO2 levels in the incubator, which can be detrimental to the cells, microorganisms, or plants being cultured.

- Requires careful maintenance: CO2 incubators need to be properly maintained and calibrated to ensure that they are operating at the correct temperature and CO2 levels. This can be time-consuming and may require specialized training.

- May not be suitable for all applications: CO2 incubators are designed for growing or culturing cells, microorganisms, or plants under controlled conditions. They may not be suitable for all applications, especially those that require different conditions or gases.

Overall, CO2 incubators offer several advantages, but they also have some potential disadvantages to consider. Whether a CO2 incubator is the right choice for your needs will depend on your specific research or laboratory requirements.

4. Cooled incubators

- It is also known as a cooling incubator. They contain a refrigeration system with heating and cooling functionality.

- It is used to incubate the culture media at temperatures below the ambient. The heating and cooling controls of this incubator should be appropriately balanced.

- The cooled incubators enable accurate temperature control and contain air circulation fans that deliver fresh air inside the chamber.

- It also contains numerous sensors which check the temperature.

- These are used in biology and microbiology labs.

Cooled incubators Advantages

Cooled incubators, also known as refrigerated incubators, are specialized pieces of laboratory equipment used to maintain a controlled, low temperature environment for growing or culturing cells, microorganisms, or plants. They are commonly used in research laboratories and other scientific settings to study the growth and behavior of cells, microorganisms, or plants under low temperature conditions.

There are several advantages to using cooled incubators:

- Controlled temperature: Cooled incubators allow you to maintain a consistent, low temperature environment for growing or culturing cells, microorganisms, or plants. This is particularly useful for studying the growth and behavior of cells, microorganisms, or plants under low temperature conditions.

- Wide temperature range: Many cooled incubators are designed to operate over a wide temperature range, from below freezing to room temperature. This allows you to study the growth and behavior of cells, microorganisms, or plants under a variety of temperature conditions.

- Energy-efficient: Cooled incubators use less energy than other types of incubators, which can save you money on energy costs and reduce your carbon footprint.

- Compact size: Cooled incubators are typically smaller and more compact than other types of incubators, which makes them a convenient and space-efficient option for laboratories and other research facilities.

- Easy to use: Cooled incubators are relatively easy to use, with intuitive controls and simple maintenance requirements.

Overall, cooled incubators are a useful tool for growing or culturing cells, microorganisms, or plants under low temperature conditions. They offer a wide range of temperature options, are energy-efficient, and are easy to use, making them a convenient and practical choice for many research applications.

Disadvantages of Cooled incubators

While cooled incubators offer several advantages, there are also a few potential disadvantages to consider:

- Limited temperature range: While many cooled incubators are designed to operate over a wide temperature range, they are limited to relatively low temperatures compared to other types of incubators. This can be a disadvantage if you need to study the growth and behavior of cells, microorganisms, or plants at higher temperatures.

- More expensive: Cooled incubators may be more expensive to purchase and operate compared to other types of incubators, especially for larger models or those with advanced features.

- Requires a stable power source: Cooled incubators rely on a consistent power supply to maintain a stable temperature. Any power outages or fluctuations can affect the temperature of the incubator, which can be detrimental to the cells, microorganisms, or plants being cultured.

- Requires careful maintenance: Cooled incubators need to be properly maintained and calibrated to ensure that they are operating at the correct temperature. This can be time-consuming and may require specialized training.

- May not be suitable for all applications: Cooled incubators are designed for growing or culturing cells, microorganisms, or plants at low temperatures. They may not be suitable for all applications, especially those that require higher temperatures.

Overall, cooled incubators offer several advantages, but they also have some potential disadvantages to consider. Whether a cooled incubator is the right choice for your needs will depend on your specific research or laboratory requirements.

5. BOD (Biological Oxygen Demand) Incubator

- In the laboratory, BOD incubators are used to produce yeast and mould.

- Also known as a low-temperature incubator, it gives a temperature range of 20-25 C.

6. Portable incubator

A portable incubator is a portable, lightweight incubator designed for use in a variety of settings, including research laboratories, educational institutions, and fieldwork. Portable incubators are typically smaller and more compact than traditional incubators, and they are designed to be easily transported and set up in different locations.

There are several types of portable incubators available, including:

- Portable cell culture incubators: These incubators are used to grow and maintain cells in a controlled environment. They are typically used in research laboratories to study the growth and behavior of cells under different conditions.

- Portable microbial incubators: These incubators are used to grow and maintain microorganisms, such as bacteria, fungi, and yeast. They are commonly used in microbiology laboratories to study the growth and behavior of microorganisms under different conditions.

- Portable plant growth incubators: These incubators are used to grow and maintain plants in a controlled environment. They are typically used in research laboratories to study the growth and development of plants under different conditions.

- Portable egg incubators: These incubators are used to incubate eggs and provide a controlled environment for the development of embryos. They are commonly used in research laboratories to study the development of eggs and embryos, and are also used in the poultry industry to incubate eggs for hatching.

Portable incubator advantage and disadvantage

There are several advantages to using a portable incubator:

- Mobility: Portable incubators are designed to be easily transported and set up in different locations. This makes them a convenient option for fieldwork or for use in locations where traditional incubators are not available.

- Compact size: Portable incubators are typically smaller and more compact than traditional incubators, which makes them a space-efficient option for laboratories and other research facilities.

- Wide range of applications: Portable incubators are available in a variety of sizes and models, with different features and capabilities. This makes them suitable for a wide range of applications, such as growing or culturing cells, microorganisms, or plants.

- Energy-efficient: Portable incubators use less energy than larger incubators, which can save you money on energy costs and reduce your carbon footprint.

There are also a few potential disadvantages to consider:

- Limited capacity: Portable incubators are typically smaller than traditional incubators, which means they have a limited capacity. This may not be suitable for large-scale applications or for growing or culturing large quantities of cells, microorganisms, or plants.

- Limited temperature range: Some portable incubators may be limited in terms of the temperature range they can maintain, which may be a disadvantage for certain applications.

- May not have advanced features: Portable incubators may not have all the advanced features and capabilities of larger incubators, such as precise temperature control or the ability to control gas concentrations.

Overall, portable incubators are a convenient and versatile option for laboratories and other research facilities that need to maintain a controlled environment for growing or culturing cells, microorganisms, or plants. However, they may have some limitations, such as a limited capacity and a limited temperature range, which may be a disadvantage for certain applications.

7. Other Types of Incubator

- Refrigerated incubators: These incubators are designed to maintain a consistent, controlled temperature below freezing. They are commonly used in research laboratories to study the growth and behavior of cells, microorganisms, or plants under low temperature conditions.

- Humidity incubators: These incubators are designed to maintain a consistent, controlled humidity level. They are commonly used in research laboratories to study the growth and behavior of cells, microorganisms, or plants under different humidity conditions.

- Cryogenic incubators: These incubators are designed to maintain a consistent, controlled temperature below freezing. They are commonly used in research laboratories to store and transport materials that must be kept at very low temperatures.

- Inverted incubators: These incubators are designed to allow the user to view and work with samples on the underside of a microscope stage or other platform. They are commonly used in research laboratories to study the growth and behavior of cells, microorganisms, or plants under inverted conditions.

- Egg incubator: An egg incubator is used to incubate eggs and provide a controlled environment for the development of embryos. It is commonly used in research laboratories to study the development of eggs and embryos, and is also used in the poultry industry to incubate eggs for hatching.

- Plant growth incubator: A plant growth incubator is used to grow and maintain plants in a controlled environment. It is typically used in research laboratories to study the growth and development of plants under different conditions.

Operating Procedure of an incubator

After preparation of culture, it needs to be stored in an incubator at the desired temperature, co2 concentration for a period of time.

- Before run an incubator make sure there are no remaining items present from the previous cycles.

- If different organisms require the same parameters then keep them in the same incubator.

- Then close the door and switch on the incubator. Make sure the door is properly closed.

- Now set the desired temperature in the controller and keep monitoring it through the thermometer.

- If any organism requires a specific concentration of CO2 or a specific humidity then we also can set them in the controller.

- After setting the parameters, place the culture plates on the perforated shelves upside down.

- It is necessary to seal the plates with adhesive tapes or are placed in plastic bags to prevent contamination.

Application of Incubator

In laboratories incubator is used for different purpose such as;

- Used to maintain the growth of different microbial cultures or cell cultures, which we can use in later.

- Sometimes they are used to enhance the growth rate of organisms.

- Some advanced incubators are used for the reproduction of microbial colonies and subsequent determination of biochemical oxygen demand.

- In zoology, they are also used for the breeding of insects and hatching of eggs.

- It also used to store different medical samples.

Advantages of Incubator

- Controlled environment: Incubators allow you to maintain a consistent, controlled environment for growing or culturing cells, microorganisms, or plants. This is particularly useful for studying the growth and behavior of cells, microorganisms, or plants under different conditions.

- Wide temperature range: Many incubators are designed to operate over a wide temperature range, from below freezing to room temperature. This allows you to study the growth and behavior of cells, microorganisms, or plants under a variety of temperature conditions.

- Controlled gas concentrations: Some incubators are equipped with a gas delivery system that allows you to control the concentration of gases such as CO2 and O2 in the incubator. This is useful for studying the effect of different gas concentrations on the growth and behavior of cells, microorganisms, or plants.

- Energy-efficient: Incubators use less energy than other types of laboratory equipment, which can save you money on energy costs and reduce your carbon footprint.

- Compact size: Incubators are typically smaller and more compact than other types of laboratory equipment, which makes them a convenient and space-efficient option for laboratories and other research facilities.

- Easy to use: Incubators are relatively easy to use, with intuitive controls and simple maintenance requirements.

Overall, incubators are a useful tool for growing or culturing cells, microorganisms, or plants under controlled conditions. They offer a wide range of temperature and gas concentration options, making them a convenient and practical choice for many research applications.

Limitations of Incubator

- More expensive: Incubators may be more expensive to purchase and operate compared to other types of laboratory equipment, especially for larger models or those with advanced features.

- Requires a stable power source: Incubators rely on a consistent power supply to maintain a stable temperature and gas concentrations. Any power outages or fluctuations can affect the temperature and gas concentrations in the incubator, which can be detrimental to the cells, microorganisms, or plants being cultured.

- May not be suitable for all applications: Incubators are designed for growing or culturing cells, microorganisms, or plants under controlled conditions. They may not be suitable for all applications, especially those that require different conditions or gases.

- Requires careful maintenance: Incubators need to be properly maintained and calibrated to ensure that they are operating at the correct temperature and gas concentrations. This can be time-consuming and may require specialized training.

Overall, incubators are a useful tool for growing or culturing cells, microorganisms, or plants under controlled conditions. However, they may have some limitations, such as a limited temperature range and the need for careful maintenance, which may be a disadvantage for certain applications.

Precautions

- Before run an incubator make sure there is enough water present underneath the shelves, otherwise the culture media will be drying out.

- Clean the incubator regularly, otherwise organisms will settle down on the shelves or the corners of the incubator.

- To avoid the condensation of water onto the media placed the plates upside down with the lid at the bottom.

- Before placing the culture plates inside the incubator make sure the desire parameters are achieved.

- Avoid repeated opening of the door when the incubator is running.

Examples of Incubators

Here is a list of top 10 incubators for laboratories:

- Thermo Fisher Scientific Forma Series II Water-Jacketed CO2 Incubator

- BINDER CB Series CO2 Incubator

- NuAire NU-5700 CO2 Incubator

- VWR In-Line HEPA Filtered CO2 Incubator

- Sanyo MCO-19AIC CO2 Incubator

- Eppendorf Incubator e CO2

- Panasonic MCO-170M CO2 Incubator

- Thermo Scientific Heracell VIOS 160i CO2 Incubator

- Panasonic MCO-20MPC CO2 Incubator

- BINDER FD Series CO2 Incubator

It’s important to note that the best incubator for a laboratory will depend on the specific needs and requirements of the laboratory. Factors to consider when choosing an incubator include the size and capacity of the incubator, the type of samples being incubated, the temperature and humidity range required, and the type of CO2 control system needed.

What are the five incubation problems?

There are several common incubation problems that may arise in a laboratory setting:

- Temperature fluctuations: Incubators should be set to a specific temperature, and fluctuations in temperature can affect the growth and development of the samples being incubated.

- Humidity issues: Incubators should be set to a specific humidity level, and deviations from this level can affect the growth and development of the samples being incubated.

- Contamination: Incubators should be kept clean to prevent contamination of the samples being incubated.

- CO2 levels: Incubators that use CO2 as a gas for incubation should maintain a specific level of CO2 in the incubator, and deviations from this level can affect the growth and development of the samples being incubated.

- Power failures: Incubators rely on a constant power supply, and power failures can affect the temperature and humidity of the incubator, potentially leading to problems with sample growth and development.

It’s important to carefully monitor incubation conditions and address any issues that may arise to ensure the success of the incubation process.

Why do incubators need CO2?

Incubators, which are devices used to incubate and hatch eggs, often include a system for maintaining a specific concentration of carbon dioxide (CO2) in the air inside the incubator. This is typically done for two main reasons:

- To regulate the humidity inside the incubator: The amount of CO2 in the air can affect the humidity inside the incubator, as CO2 can be absorbed and released by water. By maintaining a specific concentration of CO2, incubator operators can better control the humidity inside the incubator, which is important for the proper development of the eggs.

- To regulate the temperature inside the incubator: The presence of CO2 in the air can also affect the temperature inside the incubator, as CO2 is a greenhouse gas that traps heat. By controlling the concentration of CO2, incubator operators can fine-tune the temperature inside the incubator to ensure that it is optimal for the eggs being incubated.

Overall, the main goal of controlling CO2 in an incubator is to create a stable, controlled environment that is suitable for the eggs being incubated, as this can help improve the chances of successful hatching.

FAQ

Do all incubators need CO2?

Not all incubators include a system for controlling the concentration of carbon dioxide (CO2) in the air inside the incubator. Some incubators rely on other methods to regulate the humidity and temperature inside the incubator.

However, many incubators, particularly those used for incubating eggs from certain species, do include a CO2 control system. This is because the concentration of CO2 in the air can affect the humidity and temperature inside the incubator, and by controlling the CO2 concentration, incubator operators can better regulate these variables. Maintaining a stable and controlled environment inside the incubator is important for the proper development of the eggs being incubated, as it can improve the chances of successful hatching.

Ultimately, whether or not an incubator needs a CO2 control system depends on the specific requirements of the eggs being incubated and the goals of the incubator operator. Some eggs may require a specific humidity or temperature range to develop properly, and a CO2 control system may be necessary to achieve these conditions.

Why are incubators kept at 37 degrees?

Incubators are often kept at a temperature of around 37 degrees Celsius (98.6 degrees Fahrenheit) because this is the temperature that is optimal for the development of many types of eggs, including chicken eggs. This temperature is close to the body temperature of the parent bird, and it is believed to be the temperature that provides the best environment for the embryo to grow and develop.

Maintaining a stable and consistent temperature inside the incubator is important for the proper development of the eggs being incubated. If the temperature fluctuates too much or is too high or too low, it can disrupt the development of the embryo and may result in abnormal or unsuccessful hatching.

It’s worth noting that the optimal temperature for incubating eggs may vary depending on the species of the eggs being incubated. For example, some species of reptiles and birds may require slightly higher or lower temperatures than chicken eggs. Incubator operators should carefully research the specific temperature requirements of the eggs they are incubating to ensure that the incubator is set to the appropriate temperature.

How long can an incubator stay without electricity?

The length of time that an incubator can stay without electricity will depend on a variety of factors, including the type of incubator, the stage of development of the eggs being incubated, and the ambient temperature.

In general, incubators that are designed for incubating chicken eggs can usually stay without electricity for a few hours without harming the eggs, as long as the ambient temperature is not too hot or cold. However, if the incubator is without electricity for an extended period of time, the eggs may start to lose moisture and the embryos may begin to dry out, which can lead to abnormal or unsuccessful hatching.

If the eggs being incubated are at a more advanced stage of development, they may be more sensitive to changes in temperature and humidity and may be more likely to be affected by a power outage. In this case, it may be necessary to try to restore power to the incubator as soon as possible in order to maintain the optimal environment for the eggs.

It’s important to note that if the incubator is without electricity for an extended period of time, it may be necessary to discard the eggs and start again with fresh eggs. This is because the eggs may have been exposed to conditions that are not suitable for their development, which can result in abnormal or unsuccessful hatching.

Is oxygen necessary for incubator?

Oxygen is necessary for the proper development of eggs being incubated in an incubator. The embryo inside the egg uses oxygen as a source of energy for growth and development. Without an adequate supply of oxygen, the embryo may not develop properly and may be more likely to experience abnormal or unsuccessful hatching.

Incubators are designed to provide a controlled environment for the eggs being incubated, and this includes regulating the amount of oxygen in the air inside the incubator. Most incubators include a ventilation system that helps to circulate fresh air and maintain a proper oxygen level inside the incubator.

It’s worth noting that the specific oxygen requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of oxygen than others in order to develop properly. Incubator operators should carefully research the specific oxygen requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.

Does incubator need water?

Incubators typically do not require a direct water supply, as the eggs being incubated are not directly in contact with water. However, the air inside the incubator may need to be humidified in order to maintain a suitable environment for the eggs being incubated.

One way that incubators maintain humidity is by controlling the concentration of carbon dioxide (CO2) in the air. CO2 can be absorbed and released by water, and by controlling the concentration of CO2, incubator operators can regulate the humidity inside the incubator.

Another way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

Overall, while incubators do not typically require a direct water supply, they may require a source of water in order to maintain the proper humidity inside the incubator, which is important for the proper development of the eggs being incubated.

Why do you put water in an incubator?

The water in an incubator is used to help maintain the humidity inside the incubator at a suitable level for the eggs being incubated. The eggs need a certain level of humidity in order to develop properly, as the eggs absorb and release moisture during the incubation process.

One way that incubators maintain humidity is by using a water pan or tray. This is a container that holds water and is placed inside the incubator. As the water evaporates, it helps to increase the humidity inside the incubator. The water pan or tray should be kept full in order to maintain a sufficient level of humidity inside the incubator.

It’s worth noting that the specific humidity requirements for incubating eggs may vary depending on the species of the eggs being incubated. Some eggs may require higher or lower levels of humidity than others in order to develop properly. Incubator operators should carefully research the specific humidity requirements of the eggs they are incubating to ensure that the incubator is providing an optimal environment for the eggs.

Good slides have learnt a lot

Thank you

Series cooling incubators of different capacities 100….800litres….