Table of Contents

In this article, we will learn about the Membrane filtration methods, definition, applications, advantages, disadvantages. Before heading towards Membrane Filtration, you have to understand what is filtration?

Membrane filtration is a method of separating particles or molecules from a liquid or gas stream using a semi-permeable membrane. The membrane acts as a barrier, allowing some molecules to pass through while retaining others. There are several different types of membrane filtration, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. The choice of membrane and filtration method depends on the properties of the solution being filtered and the desired outcome. Membrane filtration is commonly used in water treatment, food and beverage processing, and medical applications.

Filtration

- Filtration is an effective method for the sterilization of heat-sensitive materials and it is also utilized to sterilize different liquids and gases (including air). It acts as a barrier and removes the contaminating microorganisms from the desired liquid or gas rather than destroying them.

- Mainly heat-sensitive materials are sterilized by using filtration methods. Some examples of materials which are sterilized by using filtration are antibiotic solutions, toxic chemicals, radioisotopes, vaccines, and carbohydrates.

- A filter is made of millions of pores which only allow the passage of liquid or gas through them. These pores are smaller than the microorganisms. Hence it traps those particles which are larger than the pores.

- There are present different types of filters that are used for different purposes. Each of them are made of different materials.

- A filter can be made of Asbestos pad (Seitz filter), Diatomaceous earth(Berkefeld filter), Porcelain (Chamberland-Pasteur filter), Sintered glass disks(Sintered glass filter), Cellulose(Membrane filter), Borosilicate glass fiber(HEPA filter), Clay, mud(Candle filter).

What is Membrane Filter Technique?

- In biology laboratories, membrane Filtration is widely used to sterilize liquids.

- High tensile strength polymers such as cellulose acetate, cellulose nitrate, or polysulfone are the main constituents of the membrane filter.

- The Membrane filter is also known as the molecular or biological filter.

- A membrane filter is 150μm thick and contains about millions of microscopic pores. The diameter of these spores is uniform. Based on the requirement the size of these pores is adjusted, during the process of polymerization.

- The most widely accepted membrane filter possesses a pore size of 0.22μm and 0.45μm.

- The contaminants which are larger than the pore size are trapped on the surface of the membrane filter, that’s how they filtrate the liquids.

- If the desired particles are larger than the contaminant then we can trap the desired particles or product on the membrane filter by decreasing the pore size. While the contaminants will pass through the membrane.

- The filters can be attached in parallel or series for higher-order flexibility. The throughput will increase if we add a filter of the identical pore size in parallel.

- It is an effective, accepted technique for the filtration of fluid samples.

- The quality of water and the quantity of microorganisms can be determined by using this membrane filtration method.

- The main purpose of the Membrane filtration technique is to ascertain the residence or absence of a particular coliform group that is usually existing in wastewater and groundwater.

- Sometimes, during the membrane filtration technique, the membrane filter is placed over an absorbent paper of diameter 48mm with a thickness of 0.8mm. After that, it is incubated for the extension of bacterial colonies. It absorbs 1.8-2.2ml nutrient medium.

- The absorbent pad soaks with the proper liquid broth medium to which 1.5% of agar may be supplemented.

- An absorbent pad is made of filter paper disks. It is free from growth suppressing substances such as sulphites and other compounds to enhance the growth of bacteria.

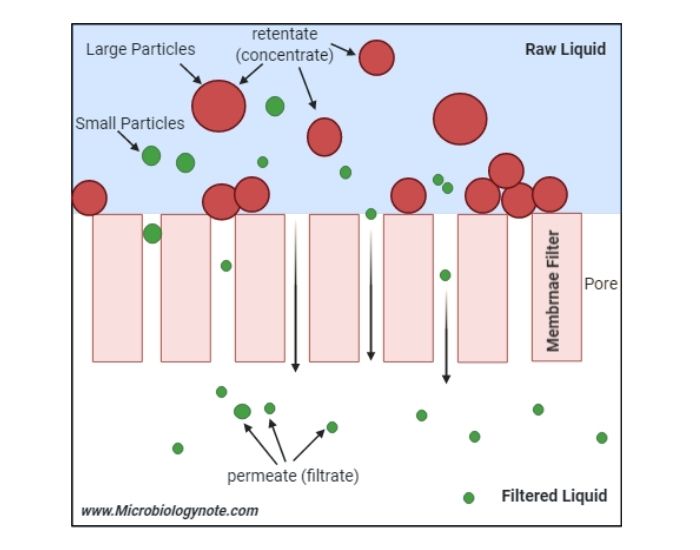

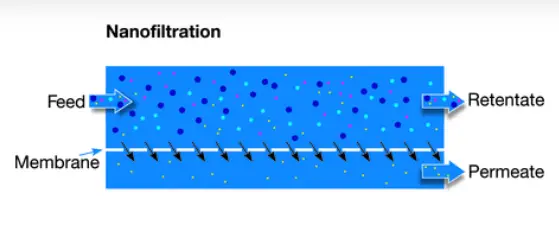

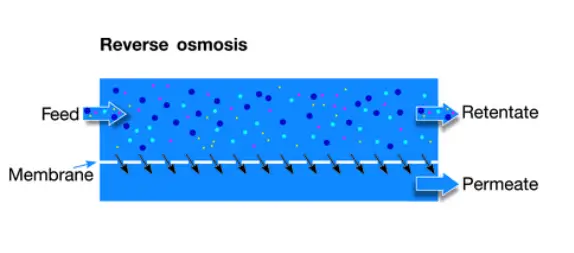

Membrane filtration mechanism

During membrane filtration, a part of fluid termed as permeate (filtrate) moves within the membrane, while other components are expelled by the membrane and clutched in the retentate (concentrate) steam.

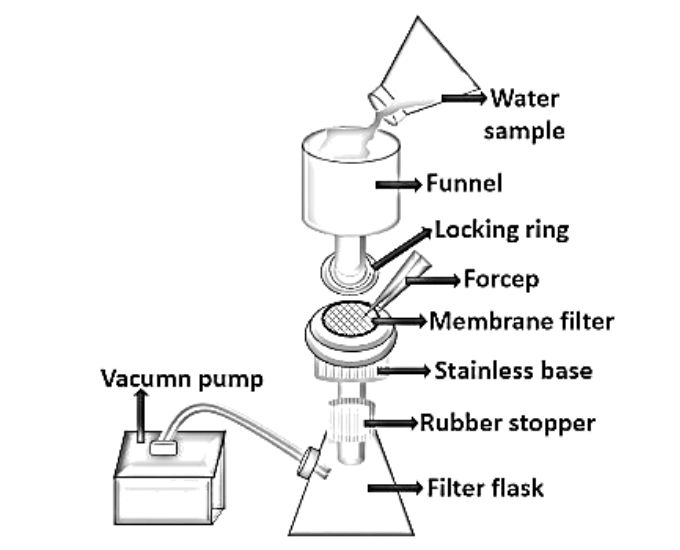

Membrane filtration Unit

- Membrane filtration unit also known as the “Membrane filtration assembly”.

- It consists of a funnel, locking ring, carbon disc, stainless base, rubber stopper, filter flask, and Vacuum pump.

- The funnel is located at the top, which is used to pass the water sample.

- A locking ring or clamp is located at the end of this stainless funnel. It controls the flow of the essay liquid sample.

- Over the carbon disk, a membrane filter is located. This carbon disc and the membrane filter is held by the stainless base.

- A rubber stopper is located at the base that controls the water flow to the filter flask.

- A Vacuum motor is connected with the filtration unit by a connector which is located at one end of the filter flask.

- The Vacuum produces a negative force which allows the suction of filtrate within the membrane filter.

Types of membrane filtration

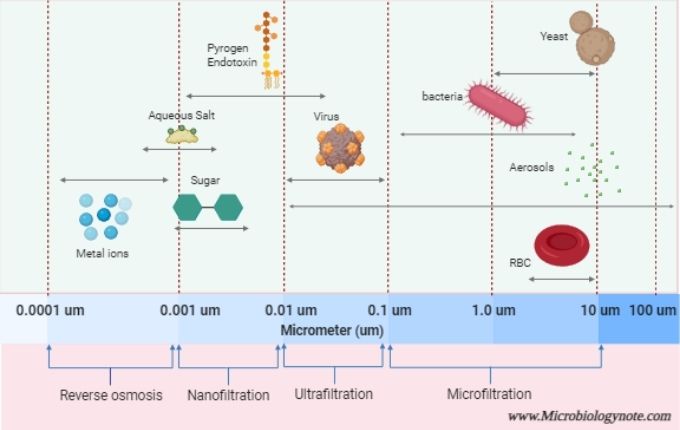

There are present mainly four types of membrane filter. These filters are classified based on their pore size such as;

- Microfiltration

- Ultrafiltration

- Nanofiltration

- Reverse osmosis (RO)

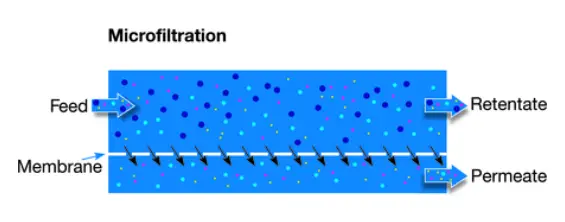

1. Microfiltration

- It separates those particles that have a size range of 0.1 to 10 μm.

- From the approximate molecular weight, it separates those macromolecules which has a molecular weight of less than 100,000 g/mol.

- It is designed to separate sediment, algae, protozoa or large bacteria from the supplied liquid sample.

- It is a pre-treatment process of ultrafiltration and a post-treatment process for granular media filtration.

Application of Microfiltration

- In the water treatment plant, it is used to separate pathogens such as the protozoa Cryptosporidium and Giardia lamblia, etc.

- In industries, it is used for the cold sterilization of beverages and pharmaceuticals. It basically eliminates bacteria and other undesired suspensions from liquids such as juice, wine, and beer in particular.

- It is also used for petroleum refining. It removes particulates from flue gases.

- In the dairy industry, it is used to remove bacteria and the associated spores from milk.

- Microfiltration is also used for the Clarification and purification of cell broths. It separates the macromolecules from proteins, large molecules, or cell debris.

- It is used for clarification of dextrose.

- Paints and Adhesives industries also use Microfiltration for their production.

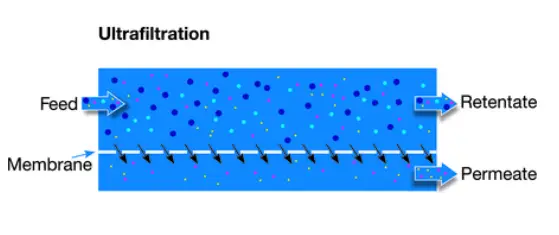

2. Ultrafiltration

- The pore size of an Ultrafiltration membrane ranges from 0.1 μm to 0.01 μm.

- It is designed to eliminate proteins, endotoxins, viruses, and silica.

- Generally, it retains those Suspended solids and solutes which possess a high molecular weight and pass those solutes that have a low molecular weight such as water.

Application of Ultrafiltration (UF)

- UF is used for the production of potable water. It removes the particulates and macromolecules from raw water.

- In dairy industries, it is used for the production of Protein concentration. During the cheese whey processing, it obtains the whey protein concentrate (WPC) and lactose-rich permeate.

- It separates effluent from the paper pulp mill.

- Used in the production of Cheese.

- It helps in the removal of bacteria from the milk.

- It is also used in wastewater treatment plants.

- Helps in Enzyme recovery.

- Used for the clarification and concentration of Fruit juice.

- In medical laboratories used for Dialysis and other blood treatments.

- Used for Desalting and solvent-exchange of proteins.

3. Nanofiltration

- The pore size of a Nanofiltration membrane ranges from 0.001 μm to 0.01 μm. The pore size of the Nanofiltration membrane is smaller than microfiltration and ultrafiltration.

- It is designed to separate multivalent ions, synthetic dyes, sugars and specific salts.

- During the development, the dimensions of pores can be controlled by pH, temperature, and time.

- The density of pores ranges from 1 to 106 pores per cm2.

- It is made of polyethylene terephthalate and other related stuff.

Application of Nanofiltration

- In fine chemistry and Pharmaceuticals industries, it is used for the recovery and management of Non-thermal solvents, Room temperature solvent exchange.

- In Oil and Petroleum chemistry, it is used to remove tar components in feed and for the Purification of gas condensates.

- In Bulk Chemistry, it is used to polish the Product, and for the Continuous recovery of homogeneous catalysts.

- In the Natural Essential Oils industries, it is used for the Fractionation of crude extracts and for the Enrichment of natural compounds Gentle Separations.

- In the Medicine industries, it is used to extract the amino acids and lipids from blood and other cell culture.

4. Reverse osmosis (RO)

- The pore size of a Reverse osmosis membrane ranges from 0.0001 μm to 0.001 μm. It has the finest separation membrane.

- It can retain all molecules except for water.

- It required osmotic pressure due to the small size of the pores.

Application of Reverse osmosis

- In households, it is used in drinking water purification systems.

- It is also used in solar-powered desalination unit to produce potable water from saline water.

- Used in reverse osmosis water purification unit (ROWPU) which is a self-contained water treatment plant.

- It is also used to purify the rainwater which is collected from storm drains.

- In power plants, it is used to remove minerals from boiler water.

- RO also used to produce deionized water.

- In food industries, it is also used for the desalination of different products.

- In Maple syrup production it is used to remove water from sap.

- Use for the production of Low alcoholic beer.

- Used in small-scale hydrogen production. It prevents the formation of mineral deposits on the surface of electrodes.

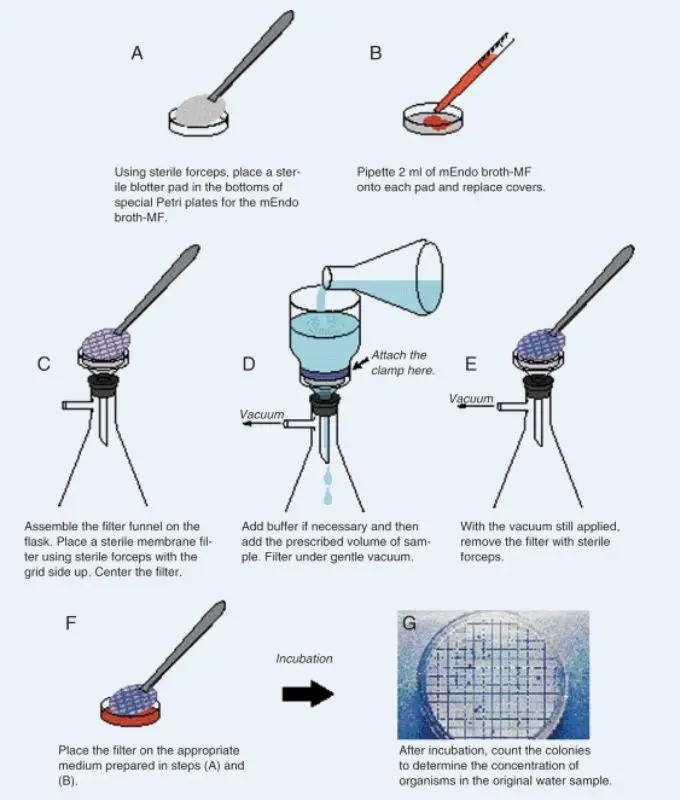

Procedure of Membrane Filtration

- First, collect the sample and dilute it.

- Select the suitable nutrient medium for isolation and enumeration of different pathogenic microorganisms.

- Transfer the medium into an absorbent pad containing a Petri plate. Immerse the absorbent pad within a liquid broth. The saturated absorbent pad will promote microbial growth.

- Use a sterilized forceps to place the membrane filter over the carbon disk.

- Sterilize the opening of the sample bottles by flame and pour the sample through the funnel.

- To draw the sample through the filter turn on the vacuum.

- After that remove the filter from the funnel by using sterile forceps and placed it over the prepared petri dish.

- Incubate the Petri plate for an appropriate period of time and at the desired temperature.

- Perform Quantitative analysis, use a colony counter to count the numbers of colonies on the Petri plate.

- Perform Qualitative analysis, to identify the isolated colony and for water quality check. Subculture the isolated colony, stain them, observe under microscope, and perform further biochemical tests to distinguish the distinct type.

Factors that affect the performance of membrane filtration

There are several factors that can affect the performance of membrane filtration, including:

- Feed water quality: The presence of suspended solids, dissolved solids, and other contaminants in the feed water can affect the performance of the membrane.

- Temperature: Higher temperatures can increase the flux (flow rate) of the membrane, but can also increase the risk of membrane fouling.

- Pressure: The applied pressure can affect the flux of the membrane. Higher pressures can increase the flux, but can also increase the risk of membrane damage.

- Membrane properties: The properties of the membrane, such as pore size, porosity, and surface charge, can affect the performance of the membrane.

- Membrane age: As a membrane ages, its performance can decline. Regular cleaning and replacement of the membrane can help to maintain performance.

- Cross-flow velocity: High cross-flow velocity can help to prevent fouling of the membrane, but can also increase the energy consumption.

- pH: The pH of the feed water can affect the performance of the membrane. Most membranes work best within a neutral pH range.

Advantages of Membrane Filtration

- It allows the filtration of any volumes of non-turbid water through the disk.

- This method is inexpensive.

- No requirement for chemicals.

- Can remove 90–100% pathogens from the water sample.

- This method is more energy efficient.

- It doesn’t denature the proteins.

- Heat sensitive media can be sterilized by using this method.

- It allows the isolation and enumeration of bacterial colonies by transferring the disk from one medium to another.

- As compared to the conventional MPN standard methods, membrane filtration provides a more rapid result. It takes 24 hours to provide the result.

- It takes less time as compared to the MPN method.

- It provides relevant and reliable results.

Disadvantages of Membrane Filtration

- The turbid water can not be used in membrane filtration.

- There may be a risk of bacterial abundance, as the water carries numerous microorganisms.

- Glass filters are breakable and can break quickly.

- The membrane filters can crack easily.

- Only liquids are sterilized by this method.

- Filters are costly to repair, mainly nano-filters.

- Constitutional restrictions of supplies used in filters alter the effectiveness of this process such as damage of glass filters, fracture of the membrane filter, and consumption of the filtrate by Sietz filter.

- Require a high differential pressure.

- Clogging can occur.

Application of Membrane Filtration

- In industries and laboratories, it is used to sterilize the heat-labile fluid materials.

- Most effective and acceptable method for filtration of drinking water.

- In the pharmaceutical, cosmetics, electronics, and food and beverage industries is is used to monitor the bacterial cells.

- Used in wastewater treatment.

- Used in cold sterilization of beverages and pharmaceuticals.

- Used for separation of milk fraction.

- Used to concentrating the proteins.

- Used for defeating skimmed milk and whey.

- Used for the partial demineralization of whey.

Most Probable Number (MPN) VS Membrane Filtration Technique

| Most Probable Number (MPN) technique | Membrane filter technique |

| Slower: requires 48 hours for a positive | More rapid: quantitative results in or presumptive positive about 18 hours |

| More labor-intensive | Less labor-intensive |

| Requires more culture medium | Requires less culture medium |

| Requires more glassware | Requires less glassware |

| More sensitive | Less sensitive |

| Result obtained indirectly by statistical approximation (low precision) | Results obtained directly by colony count (high precision) |

| Not readily adaptable for use in the field | Readily adapted for use in the field |

| Applicable to all types of water | Not applicable to turbid waters |

| Consumables readily available in most countries | Cost of consumables is high in many countries |

| May give better recovery of stressed or damaged organisms in some circumstances | No such difference observed |

FAQ

What is the use of membrane filter?

A membrane filter is a type of filter that uses a thin, porous membrane to separate particles or molecules from a liquid or gas. The membrane acts as a barrier that allows small molecules or particles to pass through, while larger particles are blocked.

Membrane filters are used in a wide range of applications, including water treatment, medical diagnostics, and industrial processes. In water treatment, membrane filters are used to remove bacteria, viruses, and other impurities from drinking water. In medical diagnostics, membrane filters are used to isolate and purify specific types of cells or molecules for analysis. In industrial processes, membrane filters are used to purify liquids and gases, such as in the production of beer, wine, and other beverages.

What does membrane filtration remove?

Increasingly, membrane techniques are used to remove bacteria, germs, particles, and natural organic material, which can lend colour, flavour, and odour to water and react with disinfectants to produce disinfection byproducts.

What is another name for membrane filtration?

Membrane filters, commonly referred to as membranes, are microporous sheets with particular pore size ratings. These are also known as microporous filters, screens, or sieves, and by the mechanism of surface capture, they retain microorganisms or particles larger than the size of their pores.

Why membranes are used for water treatment?

Membranes are used for water treatment because they are effective at removing impurities from water, including microorganisms, dissolved solids, and inorganic compounds. Membranes can also be used to remove specific contaminants, such as bacteria, viruses, and other microorganisms, from water.

Membranes have several advantages over other water treatment methods, such as chemical treatment or sedimentation. They do not require the use of chemicals, which can be harmful to the environment, and they use less energy than other methods. Membrane filtration also allows for a high degree of control over the quality of the treated water, and can be easily automated.

Additionally, membrane filtration can be used in a variety of settings, including large municipal water treatment plants, small-scale systems, and even portable treatment systems that can be used in remote locations or emergency situations. Membranes can be used in a variety of water treatment processes, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

Overall, membrane filtration is a highly efficient and cost-effective method for treating water, making it an attractive option for water treatment applications.

What is the main function of membrane filtration?

The main function of membrane filtration is to separate particles from a liquid or gas using a semipermeable membrane.

What are the types of membrane filtration?

The types of membrane filtration include microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

What are the advantages of membrane filtration?

Some advantages of membrane filtration include high efficiency, good selectivity, and low energy consumption.

What are the applications of membrane filtration?

Applications of membrane filtration include water treatment, biofiltration, industrial separations, and more.

What are the factors that affect the performance of membrane filtration?

Factors that affect the performance of membrane filtration include feed water quality, membrane material, pore size, and transmembrane pressure.

What are the common types of membrane materials used in membrane filtration?

Common types of membrane materials used in membrane filtration include cellulose acetate, polysulfone, polyamide, and polyvinylidene fluoride.

What is the mechanism of membrane filtration?

The mechanism of membrane filtration is based on the principle of size exclusion. The membrane has pores that are smaller than the particles to be separated, so the particles are unable to pass through the membrane while the liquid or gas is able to pass through.

What is the difference between microfiltration, ultrafiltration, and nanofiltration?

Microfiltration is used to remove particles larger than 0.1 microns, ultrafiltration is used to remove particles between 0.01 and 0.1 microns, and nanofiltration is used to remove particles between 0.001 and 0.01 microns.

What is the difference between reverse osmosis and ultrafiltration?

Reverse osmosis is a type of membrane filtration that removes dissolved salts and other small molecules, while ultrafiltration is used to remove particles between 0.01 and 0.1 microns.

What is the difference between dead-end and crossflow filtration?

Dead-end filtration is a method where the feed water flows into one end of the membrane and the permeate exits from the other end. In crossflow filtration, the feed water flows perpendicular to the membrane surface, allowing for continuous operation and lower fouling of the membrane.

How is the pore size of a membrane determined?

The pore size of a membrane is typically determined by measuring the size of the largest particle that can pass through the membrane.

How is the flux of a membrane determined?

The flux of a membrane is typically determined by measuring the amount of liquid or gas that can pass through the membrane over a given period of time.

How is the selectivity of a membrane determined?

The selectivity of a membrane is typically determined by measuring the ratio of the amount of a certain solute that can pass through the membrane to the amount of solvent that can pass through the membrane.

What are the common cleaning and maintenance procedures for membrane filtration?

Common cleaning and maintenance procedures for membrane filtration include chemical cleaning, backwashing, and membrane replacement.

What are the common challenges in membrane filtration and how can they be addressed?

Common challenges in membrane filtration include membrane fouling, membrane degradation, and poor selectivity. These challenges can be addressed through proper feed water treatment, regular cleaning and maintenance of the membrane, and careful selection of the membrane material and pore size to match the specific application. Additionally, using advanced technologies such as forward osmosis, and using chemicals like Hydrogen Peroxide, Chlorine and enzymes can also prevent membrane fouling.

References

- https://www.rpi.edu/dept/chem-eng/Biotech-Environ/Projects00/sterilize/filtration.html

- https://en.wikipedia.org/wiki/Microfiltration

- https://biologyreader.com/membrane-filtration-method.html

- https://www.slideshare.net/anupghimire/membrane-filtration-22725068

- https://www.slideshare.net/AkramHossain9/membrane-filtration-by-akram-hossain-food-and-process-engineering-hstu

- https://tuttnauer.com/blog/liquids-sterilization-by-filtration#:~:text=Membrane%20filters%20are%20thin%20filters,and%20thicker%20than%20membrane%20filters.

- https://www.alfalaval.us/products/separation/membranes/what-is-membrane-filtration/