Table of Contents

What is Centrifuge?

- A centrifuge is a laboratory instrument that utilizes centrifugal force to separate mixtures based on their density. It is a valuable tool in science and medical research, as well as having applications in various aspects of daily life.

- The concept of centrifugation can be traced back to Benjamin Robins, a British military engineer, who developed an early device to measure drag on objects. This device consisted of an arm rotating around an axis. Building upon this concept, the Prandtl brothers created the first practical centrifuge by refining the design. They used it to separate milk from cream by rapidly rotating a container filled with milk. The centrifugal force generated during rotation caused the heavier cream to move towards the outer part of the container, facilitating separation.

- In a centrifuge, separation is achieved by spinning a mixture at high speeds, which generates a centrifugal force. The force exerted on the mixture causes the components with different densities to separate. The heavier particles or substances move towards the outer edges of the container, while the lighter ones remain closer to the center. This enables the separation of various materials based on their size, shape, density, and viscosity.

- Centrifuges find applications in diverse fields. In scientific and medical research, they are extensively used for the purification of cells, subcellular organelles, viruses, proteins, and nucleic acids. By spinning the mixture containing these components, centrifugation helps to isolate and concentrate the desired substance from the complex mixture. This purification process is crucial for studying and understanding the specific properties and functions of these biological materials.

- Beyond the realm of scientific research, centrifuges also have practical uses in everyday life. For example, they are employed in the food industry to separate cream from milk, as well as in the production of various beverages. In wastewater treatment plants, centrifuges are utilized to separate solid particles from liquids, facilitating the purification process. Additionally, they are employed in industrial processes to separate and extract valuable substances from mixtures.

- In summary, a centrifuge is a laboratory instrument that utilizes centrifugal force to separate mixtures based on their density. It has a rich history and has evolved from early designs to become an essential tool in scientific research, medical applications, and various industries. By harnessing the power of spinning and centrifugal force, centrifuges enable the purification and separation of different substances, playing a vital role in advancing knowledge and facilitating various processes in our daily lives.

Definition of Centrifuge

A centrifuge is a laboratory instrument that uses spinning and centrifugal force to separate mixtures based on their density.

Who first invented the Centrifuge?

Overall, the centrifuge is an important tool in a wide range of scientific and industrial applications, as it allows for the efficient separation and purification of various substances.

The concept of the centrifuge has been around for centuries, and various forms of the instrument have been developed and used for different purposes. However, the modern centrifuge as we know it today was first developed in the 19th century.

In 1864, the French engineer Antonin Prandtl designed and built a prototype centrifuge that was capable of generating a centrifugal force of up to 1,000 times the force of gravity. However, this early centrifuge was not widely adopted and was not used for any practical applications.

The first practical and widely used centrifuge was developed by the German engineer Gustav de Laval in 1885. De Laval’s centrifuge was a small, hand-powered device that was used to separate milk into cream and skim milk. This early centrifuge was the precursor to the modern milk-separating machine.

In the 20th century, the centrifuge was further developed and improved, and it became a key tool in a wide range of scientific and industrial applications. Today, centrifuges are used in a variety of fields, including biology, chemistry, medicine, agriculture, and environmental science.

Principle of a Centrifuge

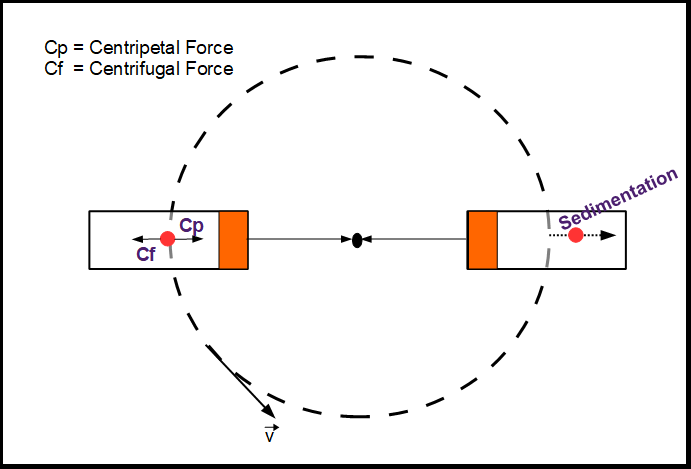

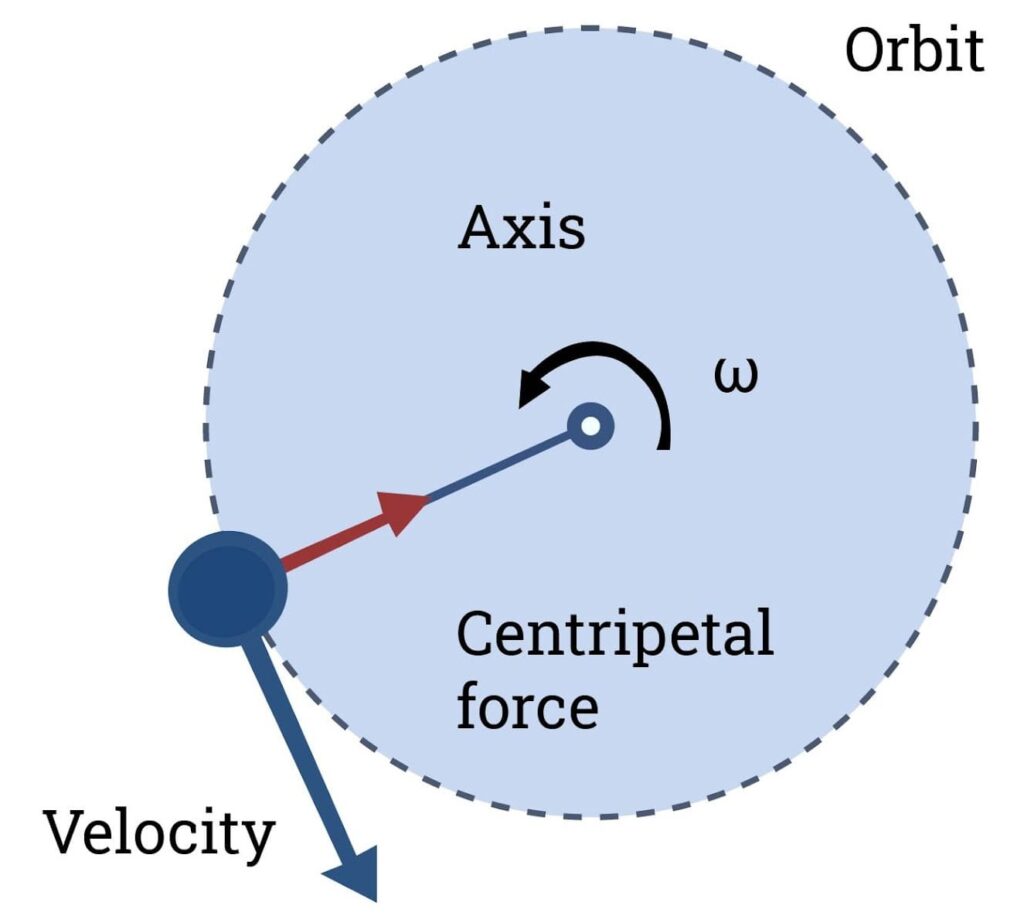

- The principle of a centrifuge is based on the sedimentation principle, which utilizes the force of gravity. When a sample is placed in a centrifuge and spun at high speeds, it creates a centrifugal force that separates the components based on their density.

- The sample, along with a liquid medium, is placed in bottles or tubes within the centrifuge’s rotor. As the rotor spins, the centrifugal force causes the denser particles or substances to settle towards the bottom of the rotor, while the lighter components remain closer to the top. This separation is known as sedimentation.

- By adjusting the speed of the rotor, the strength of the centrifugal force can be controlled. This allows for the separation and purification of substances with different densities. For example, cells, particles, or clay-like substances can be separated from a liquid medium using a centrifuge.

- The centrifuge’s principle is relatively simple: the force generated by spinning the sample causes the denser components to sediment out, while the lighter components remain suspended or rise to the top. This principle is applied in various scientific and industrial settings to purify and separate substances based on their density.

- Overall, the centrifuge plays a crucial role in many fields, including scientific research, medical diagnostics, and industrial processes. By harnessing the sedimentation principle and centrifugal force, it enables efficient separation and purification of samples, contributing to advancements in various disciplines.

The principle of a centrifuge is based on the separation of substances by density. When a sample is placed in a centrifuge and spun at high speeds, a centrifugal force is created that causes the denser components of the sample to sediment out.

The magnitude of the centrifugal force depends on the speed of the centrifuge and the size of the rotor (the part of the centrifuge that holds the sample). The higher the speed and the larger the rotor, the greater the centrifugal force that is generated.

The separation of substances in a centrifuge is based on the principle of sedimentation, which states that particles in a liquid will settle to the bottom of a container when the container is left undisturbed. In a centrifuge, the spinning motion of the rotor creates a gravitational force that is much stronger than the Earth’s gravitational force, causing the denser components of the sample to sediment out more quickly.

Overall, the principle of a centrifuge is based on the separation of substances by density, using a strong centrifugal force to accelerate the sedimentation process.

Sedimentation coefficient

- The sedimentation coefficient, also known as the Svedberg coefficient, is a measure of the rate at which a particle or molecule sediment (settles) in a centrifuge. It is expressed in Svedberg units (S), which are named after the Swedish scientist Theodor Svedberg, who developed the technique of ultracentrifugation.

- The sedimentation coefficient is determined by the size, shape, and mass of the particle or molecule. Larger, heavier particles have a higher sedimentation coefficient and will sediment more quickly in a centrifuge.

- The sedimentation coefficient is an important parameter in ultracentrifugation, a technique used to separate and purify large molecules, such as proteins and nucleic acids. It is also used to measure the size and shape of biological macromolecules, such as proteins and nucleic acids.

- In general, the sedimentation coefficient is inversely proportional to the size and mass of the particle or molecule. This means that smaller, lighter particles will have a lower sedimentation coefficient and will sediment more slowly in a centrifuge.

Factors Affecting Sedimentation coefficient

There are several factors that can affect the sedimentation coefficient of a particle or molecule in a centrifuge:

- Size and shape: The size and shape of the particle or molecule can significantly affect its sedimentation coefficient. Larger and more massive particles will have a higher sedimentation coefficient and will sediment more quickly, while smaller and lighter particles will have a lower sedimentation coefficient and will sediment more slowly.

- Molecular mass: The molecular mass of the particle or molecule can also affect its sedimentation coefficient. Higher molecular mass particles will have a higher sedimentation coefficient and will sediment more quickly, while lower molecular mass particles will have a lower sedimentation coefficient and will sediment more slowly.

- Density: The density of the particle or molecule can also affect its sedimentation coefficient. Denser particles will have a higher sedimentation coefficient and will sediment more quickly, while less dense particles will have a lower sedimentation coefficient and will sediment more slowly.

- Viscosity of the surrounding medium: The viscosity of the medium in which the particle or molecule is suspended can also affect its sedimentation coefficient. Higher viscosity media will result in a slower sedimentation rate, while lower viscosity media will result in a faster sedimentation rate.

- Temperature: The temperature of the surrounding medium can also affect the sedimentation coefficient. Higher temperatures can result in a faster sedimentation rate, while lower temperatures can result in a slower sedimentation rate.

- pH: The pH of the surrounding medium can also affect the sedimentation coefficient. Certain pH ranges can cause proteins to denature, which can affect their sedimentation coefficient.

- Concentration of particles: The concentration of particles in the surrounding medium can also affect the sedimentation coefficient. Higher concentrations of particles can result in a slower sedimentation rate, while lower concentrations of particles can result in a faster sedimentation rate.

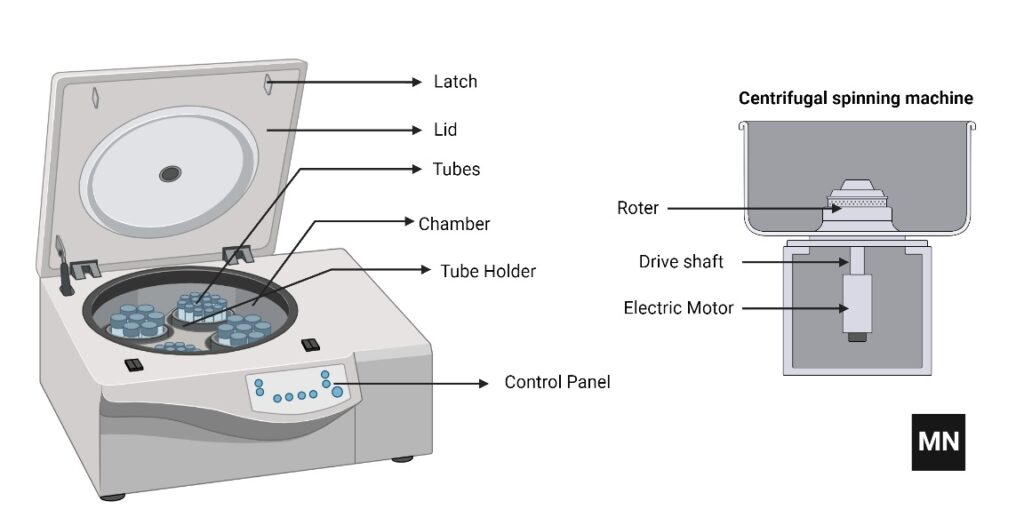

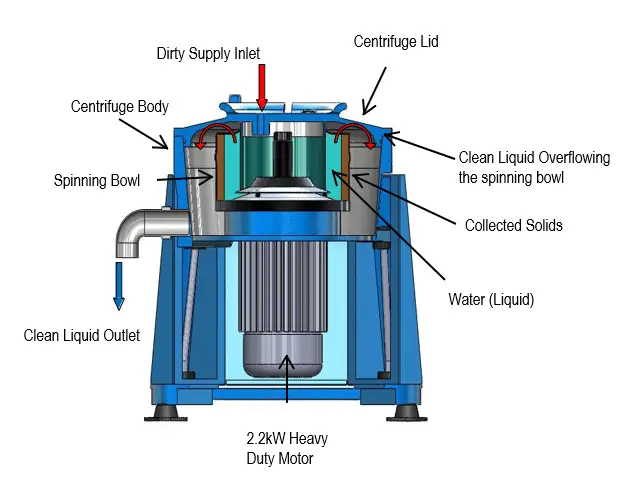

Parts of a Centrifuge

The main parts of a centrifuge include:

- Rotor: This is a spinning tube or container that holds the sample being processed. The rotor is typically made of metal or plastic and is mounted on a spindle, which allows it to rotate at high speeds.

- Driving System/Motor: This is the device that drives the rotation of the rotor. The motor is typically an electric motor, but some older or smaller centrifuges may be powered by a hand crank or a compressed air motor.

- Spindle: This is a shaft or rod that connects the rotor to the motor and allows the rotor to rotate. The spindle is typically made of metal and is mounted on bearings to reduce friction and wear.

- Containers: Several types of containers, such as test tubes, blood bags, cuvettes, centrifuge tubes, etc., are held in the rotors such that the sample rotates along as the rotor rotates.

- Control panel: This is the device that allows the user to set the speed and duration of the centrifugation process. The control panel may also include a timer and other features to allow for precise control of the process.

- Lid: This is a cover that is placed over the top of the rotor to contain the sample and protect the user from the spinning rotor. The lid may also include features such as a locking mechanism or a safety switch to prevent accidents.

- Latch: When a tube breaks, or there are other issues with the centrifuge while running, the latch keeps the lid closed.

There are many other parts that may be included in a centrifuge, depending on the specific model and its intended use. Some centrifuges may also include additional features such as temperature control, vibration isolation, or other specialized capabilities.

- Refrigeration System: The cooling system employs a completely sealed, air-tight cooled Copeland compressor unit with circuits for both refrigeration and heating control.

- Security Protection System: This security protection system includes main current protection, high temperature protection, high speed protection, balancing protection, and door cover protection.

Centrifuge Safety Features

There are several safety dangers associated with these gadgets, however they are typically fitted with safety mechanisms to protect people and the environment. Several characteristics include the following:

- Electric Lid Lock : This function prevents the lid from accidently opening while the centrifuge is in operation.

- Imbalance Sensor : The Imbalance Sensor detects when the centrifuge is not properly balanced and puts the centrifuge on pause if the vibration level increases.

- Sealed Rotors : These prevent biohazardous chemicals or substances from escaping or leaking throughout the process.

- Rotor Recognition Technology : The Rotor Recognition Technology determines which rotor is mounted and prevents the rotor from exceeding the limit operating speed.

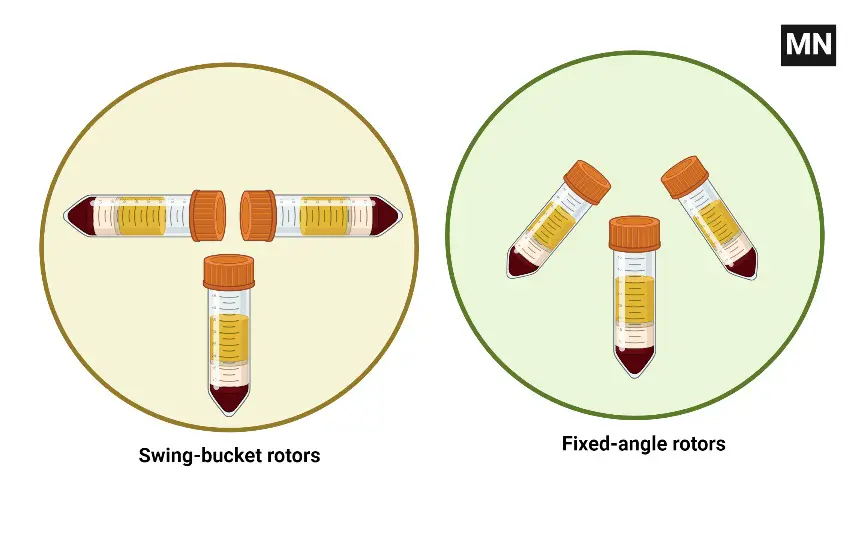

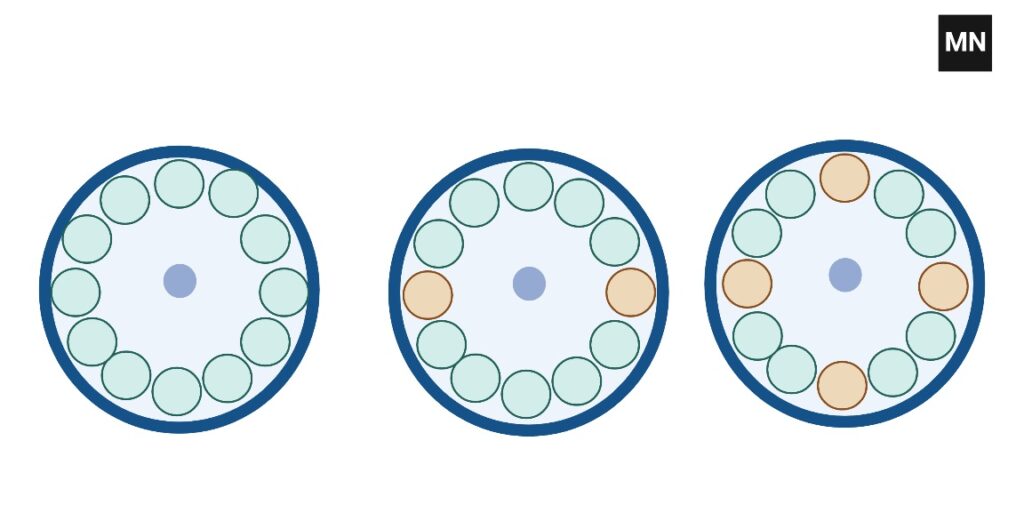

Types of Centrifuge Rotors

There are many different types of centrifuge rotors available, and the appropriate rotor type depends on the specific application and the characteristics of the sample being processed. Some common types of centrifuge rotors include:

- Fixed-angle rotors: These rotors have a fixed angle of inclination, which is typically around 15-30 degrees. They are commonly used for routine separations and for samples that are relatively dense or viscous.

- Swing-bucket rotors: These rotors have buckets that swing out from the axis of rotation when the rotor is stopped, which makes it easier to load and unload the samples. They are commonly used for samples that are sensitive to shear forces or for samples that need to be quickly cooled after centrifugation.

- Puck rotors: These rotors have a circular shape and are typically used for small samples or samples that are sensitive to shear forces.

- Vertical rotors: These rotors have a vertical axis of rotation and are commonly used for high-speed separations or for samples that are sensitive to shear forces.

- Zonal rotors: These rotors have a series of concentric zones or rings, which allows for the separation of samples based on size or density. They are commonly used for separating cells or particles.

- Continuous flow rotors: These rotors are designed for continuous processing of large volumes of samples. They are commonly used in industrial applications or for large-scale separations.

Overall, the appropriate type of rotor depends on the specific characteristics of the sample being processed and the separation requirements of the application.

Characteristics of a Centrifuge

There are several characteristics that are important to consider when selecting a centrifuge for a particular application. These include:

- Speed: The speed of the centrifuge is an important factor to consider, as it determines the strength of the centrifugal force and the separation efficiency of the instrument. High-speed centrifuges are typically used for denser samples, while lower-speed centrifuges may be more suitable for lighter samples.

- Capacity: The capacity of the centrifuge refers to the size and number of samples that it can process at one time. This is an important consideration if you need to process large quantities of samples or if you need to process multiple samples simultaneously.

- Temperature control: Some centrifuges have the ability to control the temperature of the sample during the centrifugation process. This can be important for certain types of samples, such as proteins, which may be sensitive to temperature changes.

- Vibration isolation: Centrifuges can generate significant amounts of vibration during operation, which can affect the accuracy of the results. Some centrifuges have built-in vibration isolation systems to reduce the effects of vibration on the sample.

- Safety features: Centrifuges can be dangerous if they are not used properly, so it is important to consider the safety features of the instrument. These may include safety switches, emergency stop buttons, and locking lids to prevent accidents.

- Compatibility with different rotor types: Some centrifuges are compatible with a range of different rotor types, which can be useful if you need to process a variety of sample types.

- Ease of use: Consider the user-friendliness of the centrifuge, including the control panel, the sample loading and unloading process, and the maintenance requirements.

Types of centrifugation techniques

Centrifugation is a technique used to separate substances based on their density. There are several different types of centrifugation techniques, including:

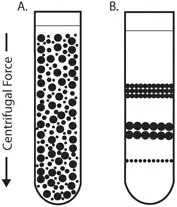

1. Sedimentation centrifugation

This is the most basic form of centrifugation, in which a sample is placed in a rotor and spun at high speeds. The denser components of the sample will sediment out towards the bottom of the rotor due to the centrifugal force, while the lighter components will remain near the top.

- Sedimentation centrifugation is a technique used to separate substances based on their density. It is the most basic form of centrifugation, and it works by spinning a sample at high speeds in a rotor, which creates a centrifugal force that causes the denser components of the sample to sediment out towards the bottom of the rotor.

- Sedimentation centrifugation is commonly used to separate cells, particles, and other denser components from a sample. It can also be used to separate different types of cells or particles based on their density. For example, red blood cells and white blood cells can be separated using sedimentation centrifugation, as they have different densities.

- There are several factors that can affect the efficiency of sedimentation centrifugation, including the size and shape of the sample, the density of the sample, the speed of the rotor, and the duration of the centrifugation process. By carefully controlling these factors, it is possible to achieve high levels of separation efficiency with sedimentation centrifugation.

- Overall, sedimentation centrifugation is a widely used technique that is simple, efficient, and relatively inexpensive, making it a valuable tool in a wide range of scientific and industrial applications.

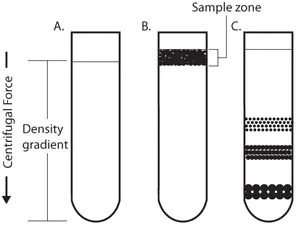

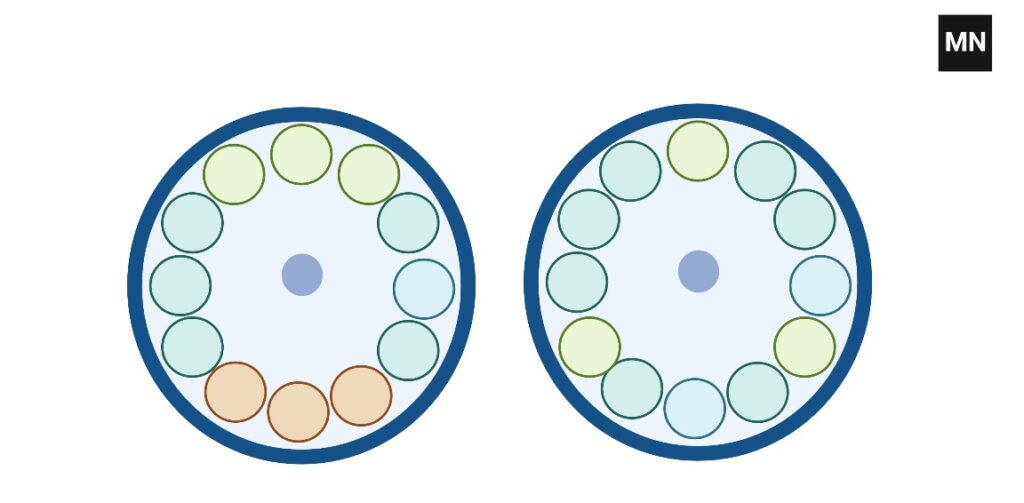

2. Density gradient centrifugation

This technique involves creating a density gradient in the sample by layering it on top of a gradient of denser solutions. The sample is then centrifuged, and the different components of the sample will sediment out at different positions along the gradient, depending on their density.

- Density gradient centrifugation is a technique used to separate substances based on their density. It involves creating a density gradient in the sample by layering it on top of a gradient of denser solutions. The sample is then centrifuged, and the different components of the sample will sediment out at different positions along the gradient, depending on their density.

- There are several types of density gradients that can be used in density gradient centrifugation, including continuous gradients and discontinuous gradients. Continuous gradients are created by gradually increasing the concentration of the denser solution from one end of the gradient to the other. Discontinuous gradients are created by layering discrete concentrations of the denser solution in the sample.

- Density gradient centrifugation is a powerful technique that allows for the separation of a wide range of substances, including cells, particles, proteins, and other biomolecules. It is commonly used in biological research and in the purification of biological samples.

- Overall, density gradient centrifugation is a useful technique for separating substances based on their density and for purifying biological samples. It is particularly useful for separating substances that are difficult to distinguish based on size or shape alone.

3. Rate-zonal centrifugation

This technique involves separating samples based on their size or shape. The sample is placed in a rotor that has a series of concentric zones or rings, and the rotor is spun at different speeds in each zone. Samples with different sizes or shapes will sediment out at different positions along the gradient.

- Rate-zonal centrifugation is a technique used to separate samples based on their size or shape. It involves placing the sample in a rotor that has a series of concentric zones or rings, and spinning the rotor at different speeds in each zone. Samples with different sizes or shapes will sediment out at different positions along the gradient.

- Rate-zonal centrifugation is a powerful technique that allows for the separation of a wide range of substances, including cells, particles, proteins, and other biomolecules. It is commonly used in biological research and in the purification of biological samples.

- There are several factors that can affect the efficiency of rate-zonal centrifugation, including the size and shape of the sample, the density of the sample, the speed of the rotor, and the duration of the centrifugation process. By carefully controlling these factors, it is possible to achieve high levels of separation efficiency with rate-zonal centrifugation.

- Overall, rate-zonal centrifugation is a useful technique for separating substances based on their size or shape and for purifying biological samples. It is particularly useful for separating substances that are difficult to distinguish based on density alone.

4. Continuous flow centrifugation

This technique involves continuously processing large volumes of samples in a specialized rotor. The samples are introduced at one end of the rotor, and the separated components are collected at the other end.

- Continuous flow centrifugation is a technique used to continuously process large volumes of samples. It involves introducing the samples at one end of a specialized rotor and collecting the separated components at the other end.

- Continuous flow centrifugation is a powerful technique that allows for the efficient separation and purification of a wide range of substances, including cells, particles, proteins, and other biomolecules. It is commonly used in industrial and environmental applications, such as the purification of water and other fluids, as well as in biological research.

- There are several factors that can affect the efficiency of continuous flow centrifugation, including the size and shape of the sample, the density of the sample, the speed of the rotor, and the duration of the centrifugation process. By carefully controlling these factors, it is possible to achieve high levels of separation efficiency with continuous flow centrifugation.

- Overall, continuous flow centrifugation is a useful technique for continuously processing large volumes of samples and for purifying a wide range of substances. It is particularly useful in industrial and environmental applications where large quantities of samples need to be processed efficiently.

5. Precipitation centrifugation

This technique involves adding a precipitating agent to a sample, which causes the components of the sample to form a precipitate. The sample is then centrifuged, and the precipitate will sediment out due to the centrifugal force.

- Precipitation centrifugation is a technique used to separate substances based on their ability to form a precipitate when exposed to certain conditions. It involves adding a precipitating agent to a sample, which causes the components of the sample to form a precipitate. The sample is then centrifuged, and the precipitate will sediment out due to the centrifugal force.

- Precipitation centrifugation is a powerful technique that allows for the separation and purification of a wide range of substances, including proteins, nucleic acids, and other biomolecules. It is commonly used in biological research and in the purification of biological samples.

- There are several factors that can affect the efficiency of precipitation centrifugation, including the nature of the sample, the type of precipitating agent used, the concentration of the precipitating agent, and the conditions under which the precipitate is formed. By carefully controlling these factors, it is possible to achieve high levels of separation efficiency with precipitation centrifugation.

- Overall, precipitation centrifugation is a useful technique for separating and purifying a wide range of substances, particularly proteins and other biomolecules. It is particularly useful for separating substances that are difficult to distinguish based on size, shape, or density alone.

Overall, these are just a few examples of the many different types of centrifugation techniques that are used in various scientific and industrial applications.

6. Isopycnic centrifugation

Isopycnic centrifugation is a technique used in biochemistry and molecular biology to separate molecules based on their density. It is often used to separate DNA or RNA molecules based on size and/or shape.

The technique involves spinning a solution containing the molecules to be separated in a special centrifuge rotor that has a gradient of density. The molecules will sediment through the gradient based on their density, with the denser molecules sedimenting further down the gradient. By carefully controlling the speed and duration of the centrifugation, it is possible to separate the molecules based on their density.

Isopycnic centrifugation is a useful tool for purifying and separating DNA and RNA molecules, and it is often used in conjunction with other techniques, such as gel electrophoresis, to further purify and characterize the molecules.

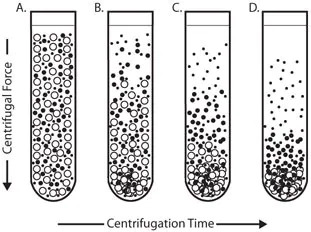

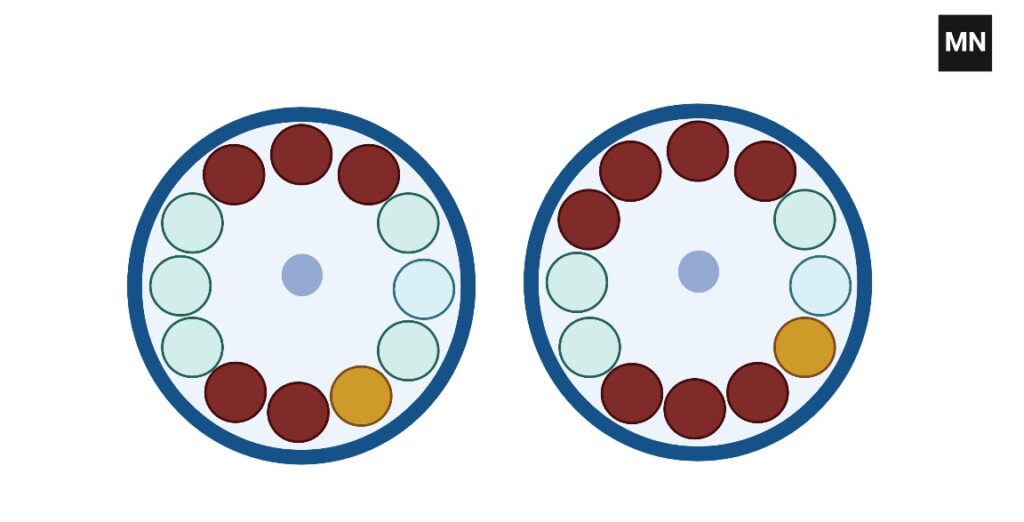

What is Differential centrifugation?

Differential centrifugation is a technique used in biochemistry and molecular biology to separate different components of a mixture based on their size, shape, and density. It is often used to purify and isolate different cellular components, such as organelles or subcellular particles.

The technique involves spinning a sample in a centrifuge at high speeds to sediment the different components based on their physical properties. The most dense and heaviest components will sediment to the bottom of the tube, while the less dense and lighter components will remain in the supernatant. By carefully controlling the speed and duration of the centrifugation, it is possible to separate the different components of the mixture.

Differential centrifugation is often used in conjunction with other techniques, such as filtration or precipitation, to further purify and isolate the components of interest. It is a useful tool for studying the structure and function of different cellular components and for preparing samples for further analysis.

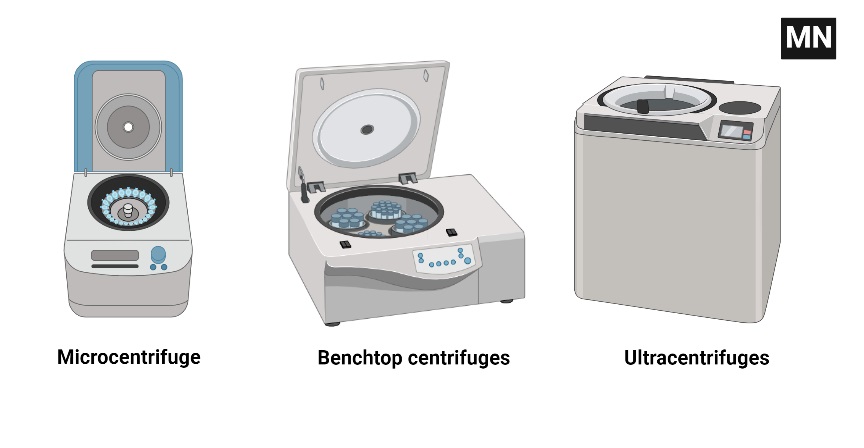

Types of Centrifuges

There are many different types of centrifuges available, and the appropriate type depends on the specific application and the characteristics of the sample being processed. Some common types of centrifuges include:

1. Benchtop centrifuges

These are small, portable centrifuges that are designed to be used on a laboratory bench or tabletop. They are commonly used for routine separations and for processing small samples.

Operating procedure Benchtop centrifuges

The operating procedure for a benchtop centrifuge may vary depending on the specific model and its intended use, but there are some general steps that are common to most benchtop centrifuges. Here is a basic outline of the operating procedure for a benchtop centrifuge:

- Familiarize yourself with the centrifuge and its controls: Before using the centrifuge, make sure you understand how to operate it and are familiar with the controls and safety features.

- Prepare the sample: Depending on the specific application, you may need to prepare the sample in a specific way before placing it in the rotor. This may involve diluting the sample, adding a precipitating agent, or performing other preparatory steps.

- Load the sample: Carefully load the sample into the rotor, making sure not to overfill it or exceed the maximum capacity of the rotor. Follow the manufacturer’s guidelines for loading the sample.

- Close the lid: Securely close the lid of the centrifuge, making sure that it is properly sealed to contain the sample and protect the user from the spinning rotor.

- Set the speed and duration: Use the control panel to set the desired speed and duration of the centrifugation process. Follow the manufacturer’s guidelines for selecting the appropriate speed and duration for your specific application.

- Start the centrifuge: Press the start button on the control panel to begin the centrifugation process. Make sure to keep your hands and other objects away from the rotor while it is spinning.

- Monitor the centrifuge: Keep an eye on the centrifuge while it is running to ensure that it is operating properly. If you notice any problems or abnormalities, stop the centrifuge immediately and troubleshoot the issue.

- Unload the sample: When the centrifugation process is complete, carefully unload the sample from the rotor. Follow the manufacturer’s guidelines for unloading the sample safely.

- Clean the centrifuge: After use, be sure to clean the rotor, the control panel, and any other parts of the centrifuge that may have come into contact with the sample. This will help to prevent contamination and ensure that the centrifuge is ready for use in the future.

Overall, it is important to follow the manufacturer’s guidelines and take proper precautions when operating a benchtop centrifuge to ensure the safety of the user and the accuracy of the results.

Applications of Benchtop centrifuges

Benchtop centrifuges are small, portable centrifuges that are designed to be used on a laboratory bench or tabletop. They are commonly used for routine separations and for processing small samples. Some specific applications of benchtop centrifuges include:

- Separating cells: Benchtop centrifuges can be used to separate cells, such as red blood cells or white blood cells, based on their density or size.

- Purifying proteins: Benchtop centrifuges can be used to purify proteins by precipitating them out of solution and collecting the precipitate after centrifugation.

- Separating particles: Benchtop centrifuges can be used to separate particles, such as viruses or bacteria, based on their density or size.

- Preparing samples for analysis: Benchtop centrifuges can be used to prepare samples for analysis by separating or concentrating the components of the sample.

- Isolating DNA or RNA: Benchtop centrifuges can be used to isolate DNA or RNA from biological samples by using techniques such as density gradient centrifugation.

Overall, benchtop centrifuges are useful tools for separating, purifying, and concentrating a wide range of substances in the laboratory. They are particularly useful for processing small samples and for routine separations.

Advantages of Benchtop centrifuges

They have several advantages over larger centrifuges, including:

- Compact size: Benchtop centrifuges are much smaller and more portable than larger centrifuges, making them easier to store and transport.

- Low cost: Benchtop centrifuges are generally less expensive than larger centrifuges, making them a more cost-effective option for many labs.

- Easy to use: Benchtop centrifuges are generally simpler to operate than larger centrifuges, making them a good choice for labs that do not have a lot of experience with centrifugation.

- Versatility: Benchtop centrifuges are versatile and can be used for a wide range of applications, including separating cells, purifying proteins, and preparing samples for analysis.

- Small sample size: Benchtop centrifuges are well-suited for processing small samples, making them a good choice for labs that do not have a lot of sample material available.

Overall, benchtop centrifuges are an important tool in many labs due to their compact size, low cost, ease of use, versatility, and ability to process small samples. They are an essential piece of equipment for many scientific and industrial applications.

Limitations of Benchtop centrifuges

Although benchtop centrifuges are useful tools for many scientific and industrial applications, they do have some limitations. Some of the main limitations of benchtop centrifuges include:

- Low maximum speed: Benchtop centrifuges generally have a lower maximum speed than larger centrifuges, which can limit their separation efficiency for denser samples.

- Small capacity: Benchtop centrifuges generally have a smaller capacity than larger centrifuges, which can be limiting for applications that require the processing of large quantities of sample material.

- Limited rotor options: Benchtop centrifuges generally have fewer rotor options than larger centrifuges, which can limit their versatility for certain applications.

- Less robust construction: Benchtop centrifuges are typically not as robustly constructed as larger centrifuges, which can make them less durable and more prone to failure.

- Limited temperature control: Some benchtop centrifuges do not have the ability to control the temperature of the sample during the centrifugation process, which can be a limitation for certain applications.

Overall, while benchtop centrifuges are useful tools for many applications, they are not suitable for all purposes and may be limited by their low maximum speed, small capacity, limited rotor options, less robust construction, and limited temperature control.

2. Floor-standing centrifuges

- These are larger centrifuges that are designed to be used on the floor or on a dedicated stand. They are commonly used for larger samples or for higher-throughput applications.

- A floor-standing centrifuge is a type of laboratory equipment that is used to separate different components of a liquid mixture based on their densities. It consists of a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor at high speeds. The rotor is surrounded by a hinged lid, which helps to contain the samples during centrifugation and may have a safety interlock to prevent the rotor from spinning if the lid is open.

- The control panel allows the user to set the desired speed and time for the centrifuge to run, and may also include displays for monitoring the status of the machine and any error messages. Some floor-standing centrifuges may have removable buckets that can be used to hold the sample tubes or bottles in place within the rotor. The brake system is used to bring the rotor to a stop after the centrifugation process is complete, and the base of the machine provides support and stability during operation.

- Floor-standing centrifuges are typically used in research laboratories and industrial settings, and are suitable for handling larger volumes of samples. They are generally more powerful and can operate at higher speeds than benchtop centrifuges, which are smaller and more compact.

Applications of Floor-standing centrifuges

Floor-standing centrifuges are widely used in a variety of scientific and industrial applications, including:

- Separating blood components: Floor-standing centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals.

Advantages of Floor-standing centrifuges

There are several advantages to using floor-standing centrifuges in a laboratory or industrial setting:

- High-speed operation: Floor-standing centrifuges are generally more powerful and can operate at higher speeds than benchtop centrifuges, which allows them to separate mixtures more efficiently and quickly.

- Large sample capacity: Floor-standing centrifuges typically have a larger capacity for samples than benchtop centrifuges, which makes them more suitable for handling larger volumes of samples.

- High-capacity rotors: Many floor-standing centrifuges have high-capacity rotors that can hold a larger number of sample tubes or bottles, which reduces the need for multiple runs and saves time.

- Wide range of rotors available: There is a wide range of rotors available for floor-standing centrifuges, including fixed angle, swing-out, and vertical rotors, which allows them to be used for a variety of applications and sample types.

- Durability: Floor-standing centrifuges are generally more durable and have a longer lifespan than benchtop centrifuges due to their larger size and heavier construction.

- Safety features: Many floor-standing centrifuges have built-in safety features, such as interlocks on the lid and emergency stop buttons, to ensure the safety of the operator and the samples.

- Versatility: Floor-standing centrifuges can be used for a wide range of applications, from medical and clinical settings to industrial processes, and can handle a variety of sample types and volumes.

Limitations of Floor-standing centrifuges

There are a few limitations to using floor-standing centrifuges in a laboratory or industrial setting:

- Size and weight: Floor-standing centrifuges are generally larger and heavier than benchtop centrifuges, which can make them difficult to move or transport.

- Cost: Floor-standing centrifuges are typically more expensive to purchase and maintain than benchtop centrifuges due to their larger size and higher capacity.

- Complexity: Some floor-standing centrifuges may have more complex control panels and require more training to operate than benchtop centrifuges.

- Power requirements: Floor-standing centrifuges typically require a higher power supply and may need to be plugged into a dedicated outlet to operate properly.

- Sample size limitations: Some floor-standing centrifuges may have limitations on the size or shape of the samples that can be processed, which may restrict their use for certain applications.

- Vibration: Some floor-standing centrifuges may generate more vibration during operation than benchtop centrifuges, which may affect the accuracy of some measurements or experiments.

- Noise: Floor-standing centrifuges can generate more noise during operation than benchtop centrifuges, which may be a concern in some laboratory or industrial settings.

3. High-speed centrifuges

- These centrifuges are designed to spin the rotor at very high speeds, typically in excess of 10,000 rpm.

- They are commonly used for denser samples or for applications that require high levels of separation efficiency.

- High-speed centrifuges are a type of laboratory equipment that are designed to spin samples at very high speeds, typically in the range of 20,000 to 100,000 revolutions per minute (rpm). They are used to separate different components of a liquid mixture based on their densities, and can be either floor-standing or benchtop models.

- High-speed centrifuges typically have a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor.

- They may also have a control panel that allows the user to set the desired speed and time for the centrifuge to run, as well as displays for monitoring the status of the machine and any error messages. Some high-speed centrifuges may have removable buckets or other accessories to hold the sample tubes or bottles in place within the rotor.

- High-speed centrifuges are used in a variety of applications, including the separation of blood components, purification of proteins, and analysis of chemical compounds. They are particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- However, they may be more expensive to purchase and maintain than lower-speed centrifuges, and may have higher power requirements and generate more vibration and noise during operation.

Applications of High-speed centrifuges

High-speed centrifuges are used in a variety of applications, including:

- Separating blood components: High-speed centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths. High-speed centrifuges may be particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization. High-speed centrifuges may be particularly useful for separating small volumes of samples or for separating samples at very high speeds, which may be required for certain applications.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry. High-speed centrifuges may be used for these applications if very high separation speeds are required.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring. High-speed centrifuges may be used for these applications if very high separation speeds are required.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals. High-speed centrifuges may be used for these applications if very high separation speeds are required.

Advantages of High-speed centrifuges

There are several advantages to using high-speed centrifuges in a laboratory or industrial setting:

- High separation speeds: High-speed centrifuges are designed to spin samples at very high speeds, typically in the range of 20,000 to 100,000 rpm, which allows them to separate mixtures more efficiently and quickly.

- Small sample volumes: High-speed centrifuges are particularly useful for separating small volumes of samples, as they can achieve high separation speeds even with small amounts of sample material.

- High-capacity rotors: Many high-speed centrifuges have high-capacity rotors that can hold a large number of sample tubes or bottles, which reduces the need for multiple runs and saves time.

- Wide range of rotors available: There is a wide range of rotors available for high-speed centrifuges, including fixed angle, swing-out, and vertical rotors, which allows them to be used for a variety of applications and sample types.

- Safety features: Many high-speed centrifuges have built-in safety features, such as interlocks on the lid and emergency stop buttons, to ensure the safety of the operator and the samples.

- Versatility: High-speed centrifuges can be used for a wide range of applications, from medical and clinical settings to industrial processes, and can handle a variety of sample types and volumes.

- High precision: High-speed centrifuges can achieve high levels of separation precision, which is important for certain applications such as the purification of proteins or the analysis of chemical compounds.

Limitations of High-speed centrifuges

There are a few limitations to using high-speed centrifuges in a laboratory or industrial setting:

- Cost: High-speed centrifuges are generally more expensive to purchase and maintain than lower-speed centrifuges due to their high-speed capabilities and specialized rotors.

- Complexity: Some high-speed centrifuges may have more complex control panels and require more training to operate than lower-speed centrifuges.

- Power requirements: High-speed centrifuges typically require a higher power supply and may need to be plugged into a dedicated outlet to operate properly.

- Sample size limitations: Some high-speed centrifuges may have limitations on the size or shape of the samples that can be processed, which may restrict their use for certain applications.

- Vibration: High-speed centrifuges may generate more vibration during operation than lower-speed centrifuges, which may affect the accuracy of some measurements or experiments.

- Noise: High-speed centrifuges can generate more noise during operation than lower-speed centrifuges, which may be a concern in some laboratory or industrial settings.

- Safety concerns: High-speed centrifuges can pose safety risks due to the high speeds at which they operate, and proper precautions must be taken to ensure the safety of the operator and the samples.

4. Refrigerated centrifuges

- These centrifuges are equipped with a refrigeration system that allows for the cooling of the sample during the centrifugation process.

- They are commonly used for samples that are sensitive to temperature changes or for applications that require the separation of temperature-sensitive samples.

- A refrigerated centrifuge is a type of laboratory equipment that is used to separate different components of a liquid mixture based on their densities. It consists of a spinning rotor that holds the sample tubes or bottles, and a drive motor that provides the power to spin the rotor at high speeds. The rotor is surrounded by a hinged lid, which helps to contain the samples during centrifugation and may have a safety interlock to prevent the rotor from spinning if the lid is open.

- In addition to the standard components of a centrifuge, a refrigerated centrifuge also includes a cooling system that maintains the temperature of the samples at a predetermined level during centrifugation. The cooling system may consist of a refrigeration unit, a cooling chamber, and a temperature control system.

- Refrigerated centrifuges are used in a variety of applications, including the separation of blood components, purification of proteins, and analysis of chemical compounds. They are particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process. However, they may be more expensive to purchase and maintain than non-refrigerated centrifuges, and may have higher power requirements and generate more vibration and noise during operation.

Applications of Refrigerated centrifuges

Refrigerated centrifuges are used in a variety of applications, including:

- Separating blood components: Refrigerated centrifuges are commonly used in medical and clinical settings to separate different components of blood, such as red blood cells, white blood cells, and plasma. They are particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Purifying proteins: Centrifugation is often used to purify and concentrate proteins from complex mixtures, such as those found in cell lysates or fermentation broths. Refrigerated centrifuges may be particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Analyzing chemical compounds: Centrifugation can be used to separate and isolate different chemical compounds in a mixture based on their densities, which can be useful for analysis and characterization. Refrigerated centrifuges may be particularly useful for separating temperature-sensitive samples or for maintaining the integrity of samples that require cold storage during the centrifugation process.

- Industrial processes: Centrifuges are also used in a variety of industrial processes, such as the separation of oil and water in the petroleum industry, or the separation of solid particles from liquids in the food processing industry. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifugation process.

- Environmental testing: Centrifuges are often used to separate and analyze different components of environmental samples, such as water or soil, for the purpose of testing and monitoring. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifugation process.

- Quality control: Centrifugation is often used as a quality control measure to ensure the purity and consistency of products, such as pharmaceuticals or industrial chemicals. Refrigerated centrifuges may be used for these applications if temperature-sensitive samples are involved or if cold storage is required during the centrifug

Advantages of Refrigerated centrifuges

Refrigerated centrifuges have several advantages over non-refrigerated centrifuges:

- Temperature control: Refrigerated centrifuges are equipped with cooling systems that allow the temperature of the samples being spun to be controlled. This is especially useful for temperature-sensitive samples or for reducing the risk of sample degradation during the spinning process.

- Increased sample stability: The ability to control the temperature of the samples being spun can also increase the stability of the samples. For example, some enzymes are more stable at lower temperatures and can be preserved for longer periods of time if stored in a refrigerated centrifuge.

- Improved separation efficiency: Refrigerated centrifuges can also improve the efficiency of separations, particularly when dealing with samples that contain large amounts of insoluble material. The cooler temperature can help to reduce the risk of sample clogging or fouling, which can occur when samples are heated up during the spinning process.

- Increased sample throughput: Refrigerated centrifuges can also increase the sample throughput of a laboratory by allowing multiple samples to be processed simultaneously. This is because the cooling system helps to dissipate the heat generated during the spinning process, which can allow the centrifuge to run for longer periods of time without overheating.

Overall, refrigerated centrifuges offer improved sample stability, increased separation efficiency, and increased sample throughput, making them an important tool for many laboratory applications.

Limitations of Refrigerated centrifuges

There are several limitations to using refrigerated centrifuges:

- Cost: Refrigerated centrifuges are generally more expensive than non-refrigerated centrifuges due to the additional cost of the cooling system and the need for regular maintenance of that system.

- Size and weight: Refrigerated centrifuges are generally larger and heavier than non-refrigerated centrifuges due to the added cooling system and the need for additional insulation. This can make them more difficult to move or transport.

- Limited temperature range: The temperature range of refrigerated centrifuges is typically limited to between 4°C and 40°C, which may not be suitable for all samples. In some cases, a wider temperature range may be required, in which case a non-refrigerated centrifuge may be more suitable.

- Risk of sample contamination: If the refrigerated centrifuge is not properly maintained and cleaned, there is a risk of sample contamination. This can occur if bacteria or other contaminants enter the centrifuge and come into contact with the samples being spun.

Overall, refrigerated centrifuges are a valuable tool for many laboratory applications, but they can be costly and may have some limitations in terms of temperature range and risk of sample contamination. It is important to carefully consider the specific needs of your laboratory and the types of samples you will be working with before deciding whether a refrigerated centrifuge is the right choice.

5. Microcentrifuges

- Microcentrifuges are small, high-speed centrifuges that are used to separate small volumes of liquid samples in the laboratory. They are commonly used to isolate DNA, RNA, and proteins, and to purify samples for downstream applications such as PCR, western blotting, and chromatography.

- Microcentrifuges are typically smaller and more compact than standard benchtop centrifuges, making them suitable for use in small laboratories or in field settings. They are also lightweight and portable, making them easy to transport to different locations.

- Microcentrifuges typically have a maximum speed of around 15,000 to 20,000 rpm, and are equipped with a rotor that can hold a range of different tube sizes, such as microtubes, PCR tubes, and Eppendorf tubes. Some microcentrifuges also have refrigeration capabilities, which can be useful for temperature-sensitive samples.

- Overall, microcentrifuges are a useful tool for separating small volumes of liquid samples in the laboratory and are commonly used in molecular biology and biochemistry research.

Applications of Microcentrifuges

Microcentrifuges are widely used in the laboratory for a variety of applications, including:

- Isolation of DNA, RNA, and proteins: Microcentrifuges are commonly used to isolate DNA, RNA, and proteins from cell or tissue samples. This is typically done by lysing the cells and then spinning the lysate in a microcentrifuge to separate the cellular components.

- Purification of samples: Microcentrifuges can also be used to purify samples for downstream applications such as PCR, western blotting, and chromatography. For example, microcentrifuges can be used to remove contaminants from a sample, or to concentrate a sample by spinning it down to a smaller volume.

- Pellet preparation: Microcentrifuges can also be used to prepare pellets of cells or other biological materials. This is typically done by spinning the cells in a microcentrifuge at high speed, which causes the cells to sediment to the bottom of the tube.

- Centrifugation of microtubes: Microcentrifuges are specifically designed to spin small tubes, such as microtubes and PCR tubes, at high speeds. This makes them an ideal tool for applications such as DNA purification and protein separation, where small volumes of sample are used.

Overall, microcentrifuges are an essential tool for many laboratory applications, particularly in molecular biology and biochemistry research.

Advantages of Microcentrifuges

There are several advantages to using microcentrifuges in the laboratory:

- Small size and compact design: Microcentrifuges are smaller and more compact than standard benchtop centrifuges, making them suitable for use in small laboratories or in field settings.

- Lightweight and portable: Microcentrifuges are lightweight and portable, making them easy to transport to different locations.

- Suitable for small volumes: Microcentrifuges are specifically designed to spin small tubes, such as microtubes and PCR tubes, at high speeds. This makes them an ideal tool for applications such as DNA purification and protein separation, where small volumes of sample are used.

- High speed: Microcentrifuges can reach speeds of up to 20,000 rpm, making them suitable for fast separations of small volumes of liquid.

- Wide range of rotor options: Microcentrifuges are equipped with a variety of rotors that can hold different tube sizes, including microtubes, PCR tubes, and Eppendorf tubes.

Overall, microcentrifuges offer a convenient and efficient way to separate small volumes of liquid samples in the laboratory, making them an important tool for many applications in molecular biology and biochemistry research.

Limitations of Microcentrifuges

There are a few limitations to using microcentrifuges in the laboratory:

- Limited sample volume: Microcentrifuges are designed to spin small volumes of liquid, typically up to 2 mL. If larger volumes of sample are needed, a larger centrifuge may be required.

- Limited capacity: Microcentrifuges typically have a limited capacity and can only hold a few tubes at a time. If more samples need to be processed simultaneously, a larger centrifuge may be required.

- Limited speed range: Microcentrifuges typically have a limited speed range of up to 20,000 rpm. If higher speeds are required, a larger centrifuge may be necessary.

- Limited temperature control: Some microcentrifuges may have limited or no temperature control, which can be a limitation for temperature-sensitive samples.

- Risk of sample loss: There is a risk of sample loss if the tubes are not properly sealed or if the rotor becomes unbalanced during the spinning process.

6. Industrial centrifuges

- These are large, heavy-duty centrifuges that are designed for use in industrial settings. They are commonly used for separating large quantities of samples or for processing highly viscous or abrasive materials.

- An industrial centrifuge is a machine that uses centrifugal force to separate substances of different densities or to remove water or other solvents from a substance. Centrifuges are used in a wide variety of industries, including pharmaceuticals, chemical processing, food and beverage production, and waste management.

Types of Industrial centrifuges

There are several types of industrial centrifuges, including:

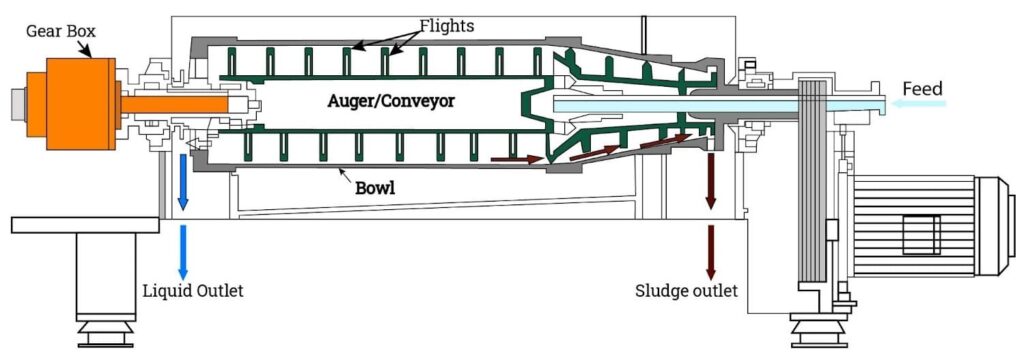

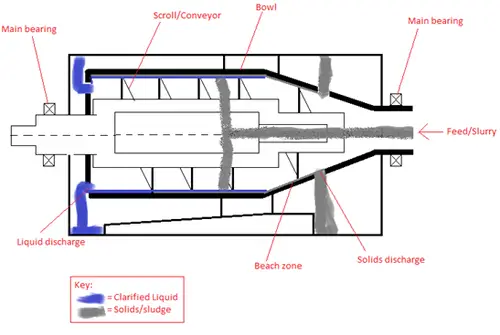

- Decanter centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a screw conveyor that helps to move the solids through the drum.

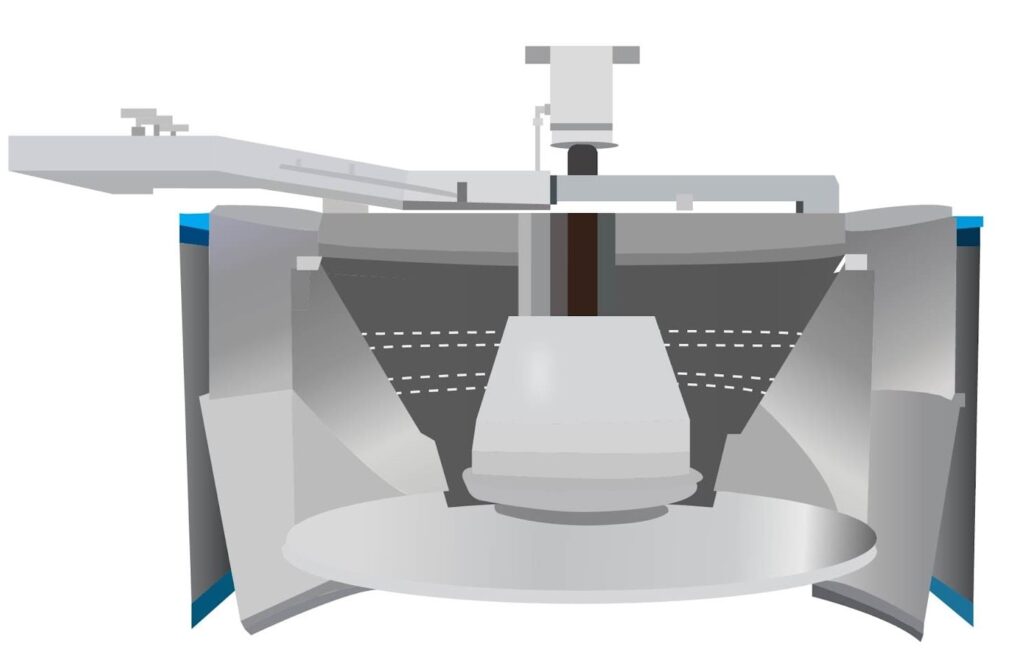

- Disk stack centrifuges: These are used to separate suspended solids from a liquid by spinning the mixture at high speeds. They consist of a vertical, cylindrical drum that rotates around a central axis, and a series of disks mounted on the drum that create a series of compartments.

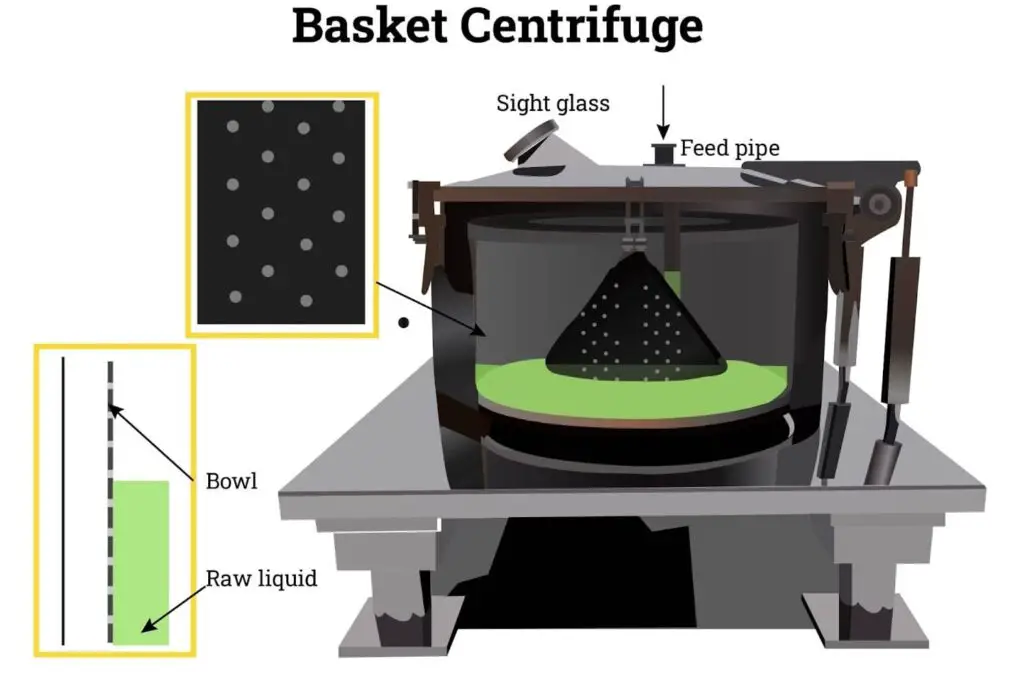

- Basket centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a basket that rotates around a central axis and is partially submerged in the liquid.

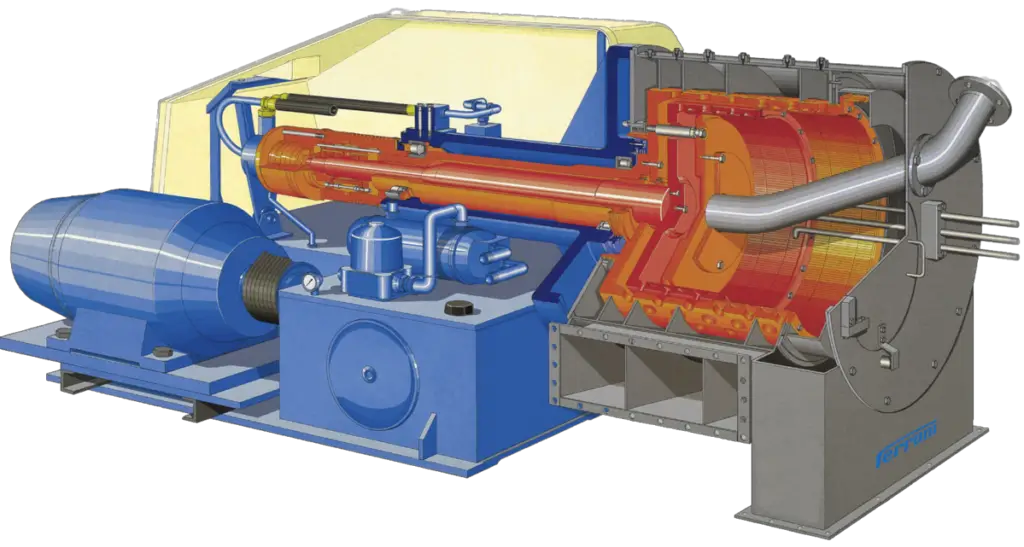

- Peeler centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of blades mounted on the drum that scrape the solids off the inner surface of the drum as it rotates.

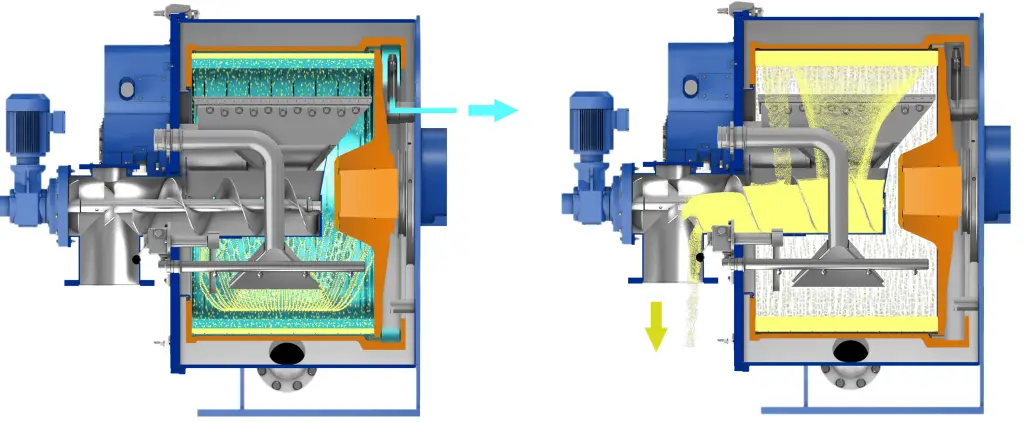

- Pusher centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of paddles mounted on the drum that push the solids through the drum as it rotates.

- Sedimentation centrifuges: These are used to separate solid particles from a liquid by spinning the mixture at high speeds. They consist of a horizontal, cylindrical drum that rotates around a central axis, and a series of blades mounted on the drum that scrape the solids off the inner surface of the drum as it rotates.

Applications of Industrial centrifuges

Industrial centrifuges are used in a variety of industries for a wide range of applications, including:

- Pharmaceuticals: Centrifuges are used in the production of drugs and other pharmaceutical products to purify and concentrate raw materials, as well as to separate solid particles from liquids.

- Chemical processing: Centrifuges are used in chemical processing to separate and purify various substances, such as oil, water, and other solvents.

- Food and beverage production: Centrifuges are used in the production of food and beverages to separate solid particles from liquids, such as in the production of milk, cream, and other dairy products.

- Waste management: Centrifuges are used in waste management to separate solid particles from liquids in order to reduce the volume of waste that needs to be disposed of.

- Oil and gas: Centrifuges are used in the oil and gas industry to separate solid particles from liquids, such as in the production of crude oil and natural gas.

- Water treatment: Centrifuges are used in water treatment to remove solid particles and other contaminants from water.

- Mining and minerals: Centrifuges are used in the mining and minerals industry to separate and purify various substances, such as minerals, ore, and coal.

Overall, industrial centrifuges are valuable tools for separating and purifying substances in a variety of industries.

Advantages of Industrial centrifuges

Some advantages of industrial centrifuges include:

- High efficiency: Centrifuges are able to separate and purify substances quickly and efficiently, making them a valuable tool for many industries.

- Can handle a wide range of materials: Centrifuges can be used to separate and purify a wide range of materials, including liquids, gases, and solids.

- Can handle large volumes: Centrifuges are able to process large volumes of material at one time, making them an efficient choice for large-scale operations.

- Can be automated: Many modern centrifuges are equipped with automation and control systems, which allows them to run with minimal supervision.

- Can be customized: Centrifuges can be customized to meet the specific needs of a given application, such as by using different sizes or types of rotors or by adding specialized equipment or features.

- Can be used for multiple applications: Centrifuges can be used for a variety of applications, including separating solid particles from liquids, purifying substances, and removing water or other solvents from a substance.

Overall, industrial centrifuges are valuable tools for separating and purifying substances in a variety of industries due to their high efficiency, versatility, and ability to handle large volumes of material.

Limitations of Industrial centrifuges

Some limitations of industrial centrifuges include:

- High energy consumption: Centrifuges require a lot of energy to operate, which can be costly and may not be environmentally friendly.

- Limited capacity: Centrifuges have a limited capacity for the amount of material they can process at one time. This means that large batches may need to be processed in multiple runs, which can be time-consuming and inefficient.

- Requires skilled operators: Centrifuges require trained operators to set them up and run them properly. This can be a challenge if trained personnel are not available.

- Can be noisy: Centrifuges can be noisy when they are operating, which can be a problem in some environments.

- Can be expensive: Centrifuges can be expensive to purchase and maintain, which may not be feasible for some businesses or organizations.

- May not be suitable for all materials: Centrifuges may not be suitable for all materials, as some materials may be too fragile or may not withstand the high centrifugal forces.

Overall, while industrial centrifuges can be effective tools for separating and purifying substances, they have some limitations that should be taken into consideration when determining whether they are the best choice for a given application.

7. Haematocrit centrifuge

- A haematocrit centrifuge is a specialized type of centrifuge that is used to separate red blood cells from other components of blood, such as plasma and white blood cells. It is often used in medical laboratories to measure the haematocrit, which is the percentage of red blood cells in a sample of blood.

- Haematocrit centrifuges typically consist of a small, portable machine that can hold a number of blood samples at once. The samples are placed in capillary tubes, which are then inserted into the machine. The machine spins the tubes at high speeds, using centrifugal force to separate the red blood cells from the other components of the blood.

- Haematocrit centrifuges are commonly used in hospitals, clinics, and other medical facilities to perform routine blood tests, such as complete blood counts (CBCs). They are also used in research laboratories to study blood and blood disorders.

- Overall, haematocrit centrifuges are important tools for separating and analyzing the components of blood, and are used in a wide range of medical and research settings.

Applications of Haematocrit centrifuge

Some applications of haematocrit centrifuges include:

- Determining the haematocrit: Haematocrit centrifuges are used to determine the haematocrit, which is the percentage of red blood cells in a sample of blood. This measurement is used to assess an individual’s overall health and to diagnose and monitor a variety of medical conditions, such as anemia and dehydration.

- Performing complete blood counts (CBCs): Haematocrit centrifuges are used in the process of performing complete blood counts (CBCs), which are routine blood tests that are used to evaluate an individual’s overall health. CBCs measure the number of red blood cells, white blood cells, and platelets in a sample of blood, as well as other important parameters, such as hemoglobin and hematocrit.

- Studying blood disorders: Haematocrit centrifuges are used in research laboratories to study blood disorders and other conditions that affect the blood. For example, they may be used to study the effects of different medications on the blood or to investigate the underlying causes of blood disorders.

- Monitoring medical treatment: Haematocrit centrifuges are used to monitor the effectiveness of medical treatment for conditions that affect the blood, such as anemia or blood loss. They can help to determine whether the treatment is working and whether any adjustments are needed.

Overall, haematocrit centrifuges are important tools for separating and analyzing the components of blood, and are used in a wide range of medical and research settings.

Advantages of Haematocrit centrifuge

Some advantages of haematocrit centrifuges include:

- Quick and accurate: Haematocrit centrifuges are able to separate and analyze the components of blood quickly and accurately, making them an efficient and reliable tool for medical and research purposes.

- Portable: Haematocrit centrifuges are typically small and portable, which makes them easy to transport and use in a variety of settings, including hospitals, clinics, and research laboratories.

- Can handle multiple samples at once: Haematocrit centrifuges are able to process multiple samples at the same time, which makes them an efficient choice for busy medical and research environments.

- Easy to use: Haematocrit centrifuges are relatively easy to operate, and do not require special training or expertise to use.

- Non-invasive: Haematocrit centrifuges do not require any invasive procedures or needles, which makes them a safe and convenient option for analyzing blood samples.

Overall, haematocrit centrifuges are valuable tools for separating and analyzing the components of blood, and offer a number of advantages over other methods of blood analysis.

Limitation of Haematocrit centrifuge

Some limitations of haematocrit centrifuges include:

- Limited to analyzing blood: Haematocrit centrifuges are only able to analyze blood samples, so they may not be suitable for studying other types of samples or substances.

- Requires skilled operators: Haematocrit centrifuges require trained operators to set them up and run them properly. This can be a challenge if trained personnel are not available.

- Can be expensive: Haematocrit centrifuges can be expensive to purchase and maintain, which may not be feasible for some organizations or facilities.

- Can be noisy: Haematocrit centrifuges can be noisy when they are operating, which can be a problem in some environments.

- May not be suitable for all samples: Haematocrit centrifuges may not be suitable for all blood samples, as some samples may contain substances that interfere with the analysis or that may not withstand the high centrifugal forces.

Overall, while haematocrit centrifuges are useful tools for separating and analyzing the components of blood, they have some limitations that should be taken into consideration when determining whether they are the best choice for a given application.

8. Low-speed centrifuges

- Low-speed centrifuges are machines that use centrifugal force to separate substances of different densities or to remove water or other solvents from a substance. They are called “low-speed” centrifuges because they operate at relatively low rotational speeds, typically in the range of 500 to 10,000 revolutions per minute (RPM).

- Low-speed centrifuges are used in a variety of industries, including pharmaceuticals, chemical processing, food and beverage production, and waste management. They are often used for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

- Low-speed centrifuges come in a range of sizes and configurations, including tabletop models for small-scale applications and larger, floor-standing models for larger volumes of material. They may be equipped with a variety of rotor types, such as fixed-angle rotors or swing-out rotors, to accommodate different types of samples.

- Overall, low-speed centrifuges are important tools for separating and purifying substances in a variety of industries, and are particularly useful for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

Applications of Low-speed centrifuges

Low-speed centrifuges are used in a variety of industries for a wide range of applications, including:

- Pharmaceuticals: Low-speed centrifuges are used in the production of drugs and other pharmaceutical products to purify and concentrate raw materials, as well as to separate solid particles from liquids.

- Chemical processing: Low-speed centrifuges are used in chemical processing to separate and purify various substances, such as oil, water, and other solvents.

- Food and beverage production: Low-speed centrifuges are used in the production of food and beverages to separate solid particles from liquids, such as in the production of milk, cream, and other dairy products.

- Waste management: Low-speed centrifuges are used in waste management to separate solid particles from liquids in order to reduce the volume of waste that needs to be disposed of.

- Oil and gas: Low-speed centrifuges are used in the oil and gas industry to separate solid particles from liquids, such as in the production of crude oil and natural gas.

- Water treatment: Low-speed centrifuges are used in water treatment to remove solid particles and other contaminants from water.

- Mining and minerals: Low-speed centrifuges are used in the mining and minerals industry to separate and purify various substances, such as minerals, ore, and coal.

Overall, low-speed centrifuges are valuable tools for separating and purifying substances in a variety of industries. They are particularly useful for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

Advantages of Low-speed centrifuges

Some advantages of low-speed centrifuges include:

- Gentle separation: Low-speed centrifuges operate at relatively low rotational speeds, which makes them suitable for applications that require gentle separation or for samples that are sensitive to high centrifugal forces.

- Can handle a wide range of materials: Low-speed centrifuges can be used to separate and purify a wide range of materials, including liquids, gases, and solids.

- Can be customized: Low-speed centrifuges can be customized to meet the specific needs of a given application, such as by using different sizes or types of rotors or by adding specialized equipment or features.

- Can be used for multiple applications: Low-speed centrifuges can be used for a variety of applications, including separating solid particles from liquids, purifying substances, and removing water or other solvents from a substance.

- Can be automated: Many modern low-speed centrifuges are equipped with automation and control systems, which allows them to run with minimal supervision.

- Can be portable: Some low-speed centrifuges are designed to be portable, which makes them easy to transport and use in a variety of settings.

Overall, low-speed centrifuges are valuable tools for separating and purifying substances in a variety of industries due to their ability to handle a wide range of materials, their customization options, and their suitability for applications that require gentle separation.

Limitation of Low-speed centrifuges

There are several disadvantages to using low-speed centrifuges:

- Limited separation capabilities: Low-speed centrifuges are not able to generate the high centrifugal forces required for the efficient separation of particles with a large size or density difference.

- Low capacity: Low-speed centrifuges can only hold a small amount of sample at a time, making them less suitable for large-scale sample processing or for handling a high volume of samples.

- Lower precision and reliability: Low-speed centrifuges are generally less precise and less reliable than higher-speed centrifuges, as they are more susceptible to vibration and imbalance. This can lead to inaccurate or inconsistent results, especially when separating delicate or sensitive samples.

- Longer separation times: Low-speed centrifuges operate at relatively low rotational speeds, so they may take longer to separate samples compared to higher-speed centrifuges.

- Higher risk of contamination: Low-speed centrifuges are more prone to contamination due to their lower rotational speeds and the fact that they do not generate as high of a force to remove contaminants.

Overall, low-speed centrifuges are best suited for relatively simple separations that do not require high levels of precision or the separation of particles with a large size or density difference. They are often used for tasks such as the sedimentation of cells or the separation of small particles from a liquid.

9. Continuous flow centrifuges

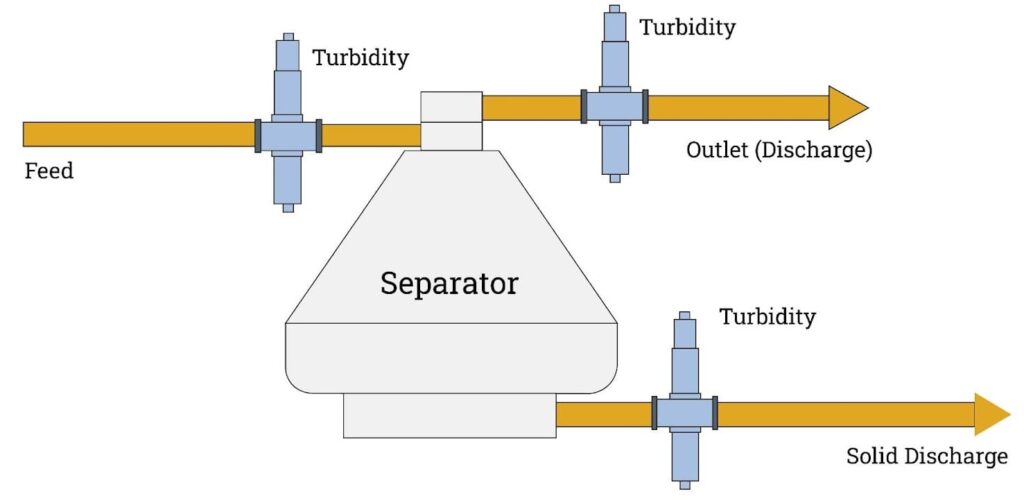

- Continuous flow centrifuges, also known as tubular or scroll centrifuges, are a type of mechanical separation device that uses centrifugal force to separate solids from liquids or to separate different types of liquids. They are called “continuous flow” centrifuges because they are designed to process a continuous flow of material, rather than batch processing like many other types of centrifuges.

- Continuous flow centrifuges consist of a cylindrical tube or “scroll” that is mounted on a horizontal axis and rotated at high speeds. The material to be separated is introduced into the scroll through a feed pipe, and as it rotates, the centrifugal force causes the denser components to move outward towards the walls of the scroll, while the lighter components remain near the center.

- The separated components are then discharged from the centrifuge through separate outlets, with the solids or denser liquids being discharged from the outer wall of the scroll and the lighter liquids being discharged from the center.

- Continuous flow centrifuges are widely used in a variety of industries, including chemical, pharmaceutical, food and beverage, and oil and gas, for tasks such as solid-liquid separation, liquid-liquid separation, and clarification of liquids. They are known for their high separation efficiency, low energy consumption, and low maintenance requirements.

Applications of Continuous flow centrifuges

Continuous flow centrifuges are widely used in a variety of industries for tasks such as solid-liquid separation, liquid-liquid separation, and clarification of liquids. Some specific applications of continuous flow centrifuges include:

- Chemical industry: Continuous flow centrifuges are used to separate various chemicals and chemical mixtures, such as pigments, dyes, and catalysts, as well as to purify and clarify chemicals.

- Pharmaceutical industry: Continuous flow centrifuges are used to separate and purify various types of pharmaceutical products, including antibiotics, hormones, and vaccines.

- Food and beverage industry: Continuous flow centrifuges are used to separate solids from liquids in the production of various food and beverage products, such as milk, juices, and beer. They are also used to clarify and purify various types of liquids, such as wine and vegetable oils.

- Oil and gas industry: Continuous flow centrifuges are used to separate and purify various types of oil and gas products, including crude oil, diesel fuel, and natural gas liquids.

- Environmental industry: Continuous flow centrifuges are used to separate and purify water and wastewater, as well as to remove solids and contaminants from water and other liquids.