Table of Contents

What is Ultrasonic Homogenizers?

- Ultrasonic homogenizers, also known as ultrasonic processors or sonifiers, are a type of tissue homogenizer that use high-frequency sound waves to disrupt cells and tissues. They work by generating high-energy sound waves in a liquid medium, which causes a phenomenon called cavitation. Cavitation is the formation and collapse of bubbles in a liquid, caused by the sound waves. The collapse of these bubbles generates very high localized pressures and temperatures, which can effectively disrupt cells and tissues.

- Ultrasonic homogenizers have a wide range of applications in biology, biochemistry, and other fields of research. They are particularly useful for homogenizing samples that are difficult to disrupt using other methods, such as samples that are hard, heat-sensitive, or have high viscosity. Ultrasonic homogenizers can also be used to extract biomolecules from cells and tissues, and to create fine emulsions and suspensions.

- Ultrasonic homogenizers are available in different designs and configurations, including benchtop and handheld models. They can be used with a wide range of sample sizes, from small volumes to large-scale samples.

- It’s important to note that ultrasonic homogenization may not be suitable for all types of samples, and that some samples may require special precautions or modifications to the ultrasonic homogenization process to prevent damage to the sample or the homogenizer. Therefore, it’s important to choose the right one for your specific needs, and to follow the manufacturer’s instructions and safety guidelines when using any ultrasonic homogenizer.

Principle of Ultrasonic Homogenizers

The ultrasonic power supply converts line voltage to 20 kHz electrical energy at high frequency. This electrical energy is sent to the probe, which converts it into mechanical energy. The probe’s vibrations are connected to and amplified by the titanium tip. This longitudinal vibration is transmitted to the titanium tip immersed in the solution by the vibrating probe. Cavitation ensues, wherein briefly produced minute vapour bubbles implode, creating intense infinitesimal shock waves to radiate throughout the solution in close proximity to the radiating face of the tip.

When ultrasonic homogeizers are used for applications such as mixing, dispersing, and emulsifying, the goal is to minimise small particles or droplets in a liquid or slurry in order to enhance the mixture’s homogeneity and stability. These particles (dispersed phase) could be solids or liquids. A decrease in the average particle diameter increases the number of individual particles.

This decreases the average distance between particles and increases their surface area. The graph (click to view bigger) illustrates the relationship between particle diameter and total surface area. Surface area and average particle distance can affect a liquid’s rheology. If there is a disparity in specific gravity between the particles and the liquid, the homogeneity of the mixture can affect the dispersion’s stability. If the majority of particles have the same particle size, the tendency to agglomerate during settling or rising is reduced because particles with the same size settle or rise at the same rate.

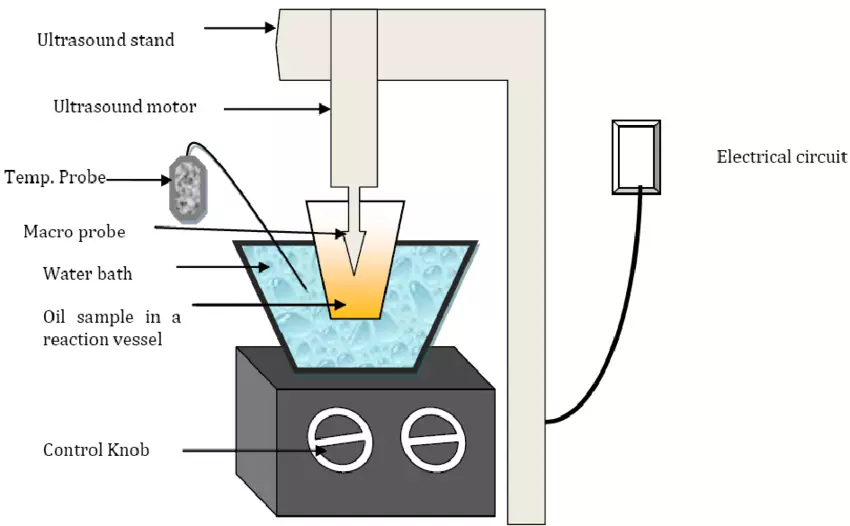

Parts of Ultrasonic Homogenizers

The specific parts of an ultrasonic homogenizer can vary depending on the type of ultrasonic homogenizer being used, but here are some common parts that are found in most ultrasonic homogenizers:

- Ultrasonic generator: This is the main control unit of the ultrasonic homogenizer. It converts electrical energy into high-frequency sound waves.

- Transducer: This is the part of the homogenizer that converts the electrical energy from the generator into mechanical energy in the form of sound waves. It is usually made of a piezoelectric material that expands and contracts when an electrical current is applied to it.

- Horn: This is the part of the homogenizer that amplifies the mechanical energy from the transducer and directs it into the liquid sample.

- Sample chamber or beaker: This is where the sample is placed for homogenization. It can be made of glass, plastic, or stainless steel.

- Power switch: This controls the power to the generator.

- Timer: This allows the user to set the homogenization time.

- Amplitude control: This controls the intensity of the ultrasonic energy and helps to ensure that the sample is homogenized to the desired particle size.

- Safety switch: This prevents the homogenizer from operating when the lid or cap is not properly secured.

- Fuse: This protects the homogenizer from damage due to power fluctuations or electrical overload.

- Additional parts may include a cooling system, pressure gauge, and sample collection vessels.

It’s important to refer to the manufacturer’s instructions for the specific ultrasonic homogenizer being used, and to follow appropriate safety precautions while working with the homogenizer.

Types of Ultrasonic Homogenizers

There are several types of ultrasonic homogenizers, each with their own advantages and disadvantages. Some common types include:

- Batch ultrasonic homogenizers: These are designed for homogenizing small to medium-sized samples. They are easy to operate, and have a simple design. Examples include benchtop sonifiers and handheld sonifiers.

- Flow-through ultrasonic homogenizers: These are designed for homogenizing large-scale samples, and involve continuously passing a sample through an ultrasonic cell. They are typically more complex and require more maintenance than batch ultrasonic homogenizers, but they can process large volumes of samples quickly and efficiently.

- Immersion ultrasonic homogenizers: These are similar to batch ultrasonic homogenizers, but involve immersing the sample in an ultrasonic bath. They are useful for homogenizing large-scale samples, but not as efficient as flow-through ultrasonic homogenizers.

- High-intensity ultrasonic homogenizers: These are specialized ultrasonic homogenizers that use high power and high frequency to generate intense ultrasonic energy, allowing for the homogenization of tough samples such as bone and teeth.

It’s important to note that different types of ultrasonic homogenizers may be more or less suitable for different types of samples and applications, so it’s important to choose the right one for your specific needs. Additionally, one should be aware of the specific parameters of ultrasonic homogenization such as frequency, power and time, that can affect the efficiency and integrity of the sample.

Operating Procedure of Ultrasonic Homogenizers

The operating procedure for ultrasonic homogenizers can vary depending on the specific model and type of ultrasonic homogenizer being used, but here is a general overview of the process:

- Prepare the sample: Depending on the type of sample and the ultrasonic homogenizer being used, it may be necessary to cut the tissue into small pieces, grind it, or otherwise prepare it for homogenization. It’s also important to prepare a buffer or solvent that is compatible with the ultrasonic homogenizer, and that can protect the integrity of the molecules being extracted and also help to dissolve the sample for better extraction.

- Place the sample in the sample chamber or beaker: Carefully pour the sample into the sample chamber or beaker, making sure that the level of the sample is appropriate for the size and type of the ultrasonic homogenizer being used.

- Secure the lid or cap: Make sure the lid or cap is properly secured to prevent any splashes or spills.

- Turn on the ultrasonic homogenizer: Turn on the power switch to start the ultrasonic homogenizer.

- Adjust the settings: Adjust the amplitude control, timer, and other settings as needed to ensure that the sample is homogenized to the desired particle size.

- Homogenize the sample: Allow the ultrasonic homogenizer to homogenize the sample for the desired time.

- Check the homogenized sample: It’s important to check the homogenized sample to ensure that the particles are small enough and the sample is homogenous.

- Extract the desired components: The homogenized sample can then be used to extract the desired components, such as proteins or nucleic acids, using methods such as centrifugation or chromatography.

- Store the extracted sample: Finally, it’s important to store the extracted sample in a way that preserves its integrity, such as freezing it at -80C or keeping it at 4C.

- Clean and maintain the ultrasonic homogenizer: Clean and properly maintain the ultrasonic homogenizer according to the manufacturer’s instructions, to ensure optimal performance and longevity.

It’s important to follow the manufacturer’s instructions for the specific ultrasonic homogenizer being used and to use appropriate safety precautions while working with the homogenizer.

Applications of Ultrasonic Homogenizers

Ultrasonic homogenizers are used in a variety of applications, including:

- Cell lysis and tissue homogenization: Ultrasonic homogenizers can be used to disrupt cells and tissues, making it easier to extract DNA, RNA, and proteins.

- Emulsification and dispersion: Ultrasonic homogenizers can be used to create stable emulsions and suspensions of immiscible liquids, such as oil and water.

- Nanoparticle and micelle production: Ultrasonic homogenizers can be used to create nanoparticles and micelles, which are useful in drug delivery and other applications.

- Food and beverage processing: Ultrasonic homogenizers can be used to homogenize and emulsify food and beverage products, such as milk and cream, to improve texture and stability.

- Industrial processes: Ultrasonic homogenizers can also be used in various industrial process such as paint and ink production, cosmetics manufacturing, and chemical synthesis.

- Environmental and water treatment: Ultrasonic homogenizers can be used to aid in the treatment of wastewater and other environmental samples.

Advantages of Ultrasonic Homogenizers

Ultrasonic homogenizers are a popular choice for many applications in biology, biochemistry, and other fields of research, because they offer many advantages over other methods of tissue disruption. Some of the advantages of ultrasonic homogenizers include:

- High efficiency: Ultrasonic homogenizers can quickly and effectively disrupt cells and tissues to release intracellular components, such as proteins and nucleic acids, for further analysis.

- Versatility: Ultrasonic homogenizers can be used to homogenize a wide range of tissue types and samples, including soft and hard tissues, plant and animal materials, and microorganisms.

- Ability to maintain sample integrity: Ultrasonic homogenizers can be designed to minimize damage to delicate biomolecules, such as proteins and nucleic acids, during the homogenization process.

- High-throughput: Ultrasonic homogenizers can be used to process large numbers of samples simultaneously, which can help to increase the speed and efficiency of research.

- Scalability: Ultrasonic homogenizers can be used to process small samples or large-scale samples, depending on the specific needs of the experiment.

- Automation: Many ultrasonic homogenizers are available with automated protocols, which can help to reduce the chances of human error and increase the reproducibility of results.

- High-intensity: Ultrasonic homogenizers are able to generate intense ultrasonic energy, allowing for the homogenization of tough samples such as bone and teeth.

- Cost-effective: Ultrasonic homogenizers are relatively cost-effective in comparison to other methods of tissue disruption.

It’s important to note that different types of ultrasonic homogenizers may be more or less suitable for different types of samples and applications, so it’s important to choose the right one for your specific needs, and to follow the manufacturer’s instructions and safety guidelines when using any ultrasonic homogenizer.

Disadvantages of Ultrasonic Homogenizers

Ultrasonic homogenizers have some disadvantages, including:

- High cost: Ultrasonic homogenizers can be expensive, especially for high-powered models.

- Limited sample volume: Ultrasonic homogenizers typically have a limited sample volume capacity, which can make them less suitable for large-scale applications.

- Noise: Ultrasonic homogenizers can be loud, which can be a problem in laboratory settings.

- Fragility of samples: Some samples can be sensitive to ultrasonic energy, which can cause damage or degrade the quality of the sample.

- Heating: Ultrasonic homogenizers can generate heat, which can affect the temperature-sensitive samples.

- Maintenance: Ultrasonic homogenizers require regular cleaning and maintenance to ensure they continue to function properly.

- Incompatibility with certain materials: Ultrasonic homogenizers are not suitable for use with some materials, such as certain types of glass and plastics, which may shatter or melt under the intense energy of the ultrasound.

- Limited compatibility with certain chemical solutions: Ultrasonic homogenizers may not work well with certain types of chemicals, so it’s necessary to be careful when choosing the right solution for a specific application.

References

- Onaneye-Babajide, Omotola & Petrik, Leslie & Bamikole, Amigun & Farouk, Ameer. (2010). Low-Cost Feedstock Conversion to Biodiesel via Ultrasound Technology. Energies. 3. 10.3390/en3101691.

- https://www.fishersci.com/us/en/browse/90180027/ultrasonic-homogenizers?page=1

- https://www.biologics-inc.com/ultrasonic-homogenizers.html

- https://www.labcompare.com/General-Laboratory-Equipment/563-Ultrasonic-Homogenizer-Laboratory-Homogenizers-Sonicator/

- https://www.labtron.com/ultrasonic-homogenizer-sonicator

- https://www.omni-inc.com/omni-sonic-ruptor-400-ultrasonic-homogenizer.html

- https://ultrasonichomogenizer.com/

- https://homogenizers.net/pages/ac-ultrasonic-homogenization

- https://homogenizers.net/collections/sonic-homogenizers-sonicators

- https://www.hielscher.com/homogenize_01.htm