Table of Contents

- Canning is one of the most essential methods for preserving food for lengthy periods of time. Typically, food is held in metal containers and treated with heat. The heat treatment differs based on the food type.

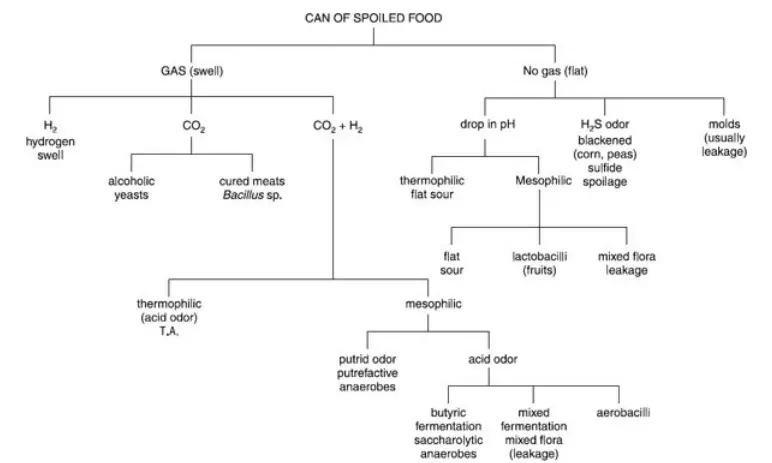

- There is always the possibility that microbes will survive improper heat treatment, resulting to food deterioration.

- Typically, there are few instances of food spoiling in cans. The can’s spoiling may be caused by biological or chemical agents, or a combination of both.

- Biological spoiling is generally caused by microbial growth, whereas chemical deterioration is caused by hydrogen created as a result of the reaction between acid in the food and iron on the container.

- In addition to high summer temperatures and high altitudes, swelling can be exacerbated by high summer temperatures and elevations.

- Other variables, such as overfilling, buckling, denting, or closing the can while it is still cool, may also contribute to the deterioration of canned foods.

Causes of Canned Foods Spoilage

- The deterioration of heated foods may have chemical, biological, or both causes. The most significant type of chemical deterioration of canned foods is hydrogen swell, which occurs when the acid of a food reacts with the iron of the can, releasing hydrogen gas under pressure.

- The presence of soluble sulphur and phosphorus compounds promotes hydrogen swelling. (1) browning of the interior of the can; (2) discoloration of the food; (3) creation of off-flavors in the food; (4) cloudiness of liquors or syrups. (5) metal corrosion or perforation, and (6) loss of nutritional value.

- Biological deterioration of canned foods by microorganisms may happen from either or both of the following: (1) survival of organisms after the delivery of the heat treatment; or (2) leakage of the container after the heat procedure, allowing organisms to enter.

- Mild heat treatments may only be sufficient to allow foods to be successfully stored for brief durations with the assistance of another preservation method, such as refrigeration.

- Microorganisms that have survived are likely to be of various types and may even contain vegetative cells.

- The processing of meat loaves and the pasteurisation of milk are examples of such operations involving low heat.

- The processing of acidic foods, such as fruits, at temperatures reaching 100 degrees Celsius kills all vegetative cells of bacteria, yeasts, and moulds, as well as their spores and certain bacterial spores.

- Typically, the only survivors are spores of bacteria, which cannot survive in an extremely acidic diet. Extremely heat-resistant bacterial spores are typically the only survivors of heat treatments such as steam under pressure.

- Microorganisms that enter through container leaks can be of numerous types and are not necessarily resistant to heat.

- Leakage and consequent deterioration of canned food may be caused by mechanically damaged empty cans with defective side and end seams; harsh handling of filled cans may also cause damage.

- Microorganisms may enter through the polluted outside surfaces of filled cans, especially if the cans are wet, or from contaminated cooling water following the heating process.

- Leakage may also result in a loss of can vacuum, which promotes chemical and microbiological decomposition of the food.

- Entrant microorganisms will be responsible for spoilage occurring from a leaking container.

- The presence of low-heat-resistance organisms, especially in large numbers, implies leaking.

Appearance of The Unopened Container

- Typically, the ends of a food can are referred to as flat, but they are actually slightly concave, and the container contains a partial vacuum.

- If internal pressure increases, the can undergoes a sequence of deformations and is referred to progressively as a flipper, springer, soft swell, and hard swell.

- One of the flat ends of a flipper will become convex when the side of the can is struck with sufficient force or when the temperature of the contents rises.

- Both ends of a springer can are bulged, but one or both will remain concave when pushed in, or if one bulged end is put in, the opposing flat end will pop out.

- Some use the terms “flipper” and “springer” to refer to slight pressures in the can that are not caused by gas production but rather by factors such as a poor exhaust, overfilling, denting of the can, changes in temperature, etc. However, the can may exhibit the same external characteristics at the onset of gas production from a microbial, chemical, or both causes.

- Both ends of a soft swell can are bulged, but the gas pressure is low enough to allow manual denting of the ends.

- Internal gas pressure within a hard swell is so high that it is impossible to dent the ends by hand. Frequently, the high gas pressures bend or buckle the cans’ ends or side seams.

- The final stage involves bursting the can, typically via the side seam, but occasionally through the end seals.

- A breather is a container with a minute leak that allows air to travel in and out but not necessarily germs.

- Before and after opening the can, the following flaws are observed: dents, which may be the cause of a flipper; rust; perforations; poor side seam or end seals; and corrosion.

- The glass food container under gas pressure may have a bulged or detached lid, or food may have leaked through the shattered seal.

- It is possible to view signs of microbial development through the glass sides, including gas bubbles, cloudiness, and growth films.

Types of Biological Spoilage of Canned Foods

Typically, types of microorganism-induced spoiling of canned foods are separated into those caused by thermophilic bacteria and those caused by mesophilic microorganisms. Other approaches for categorising types of food spoilage are based on the types of changes that occur in the food, such as putrefaction, acid generation, gas formation, and blackening. The types of rotting can also be categorised according to the foods involved. The three most significant types of biological spoiling of commercially canned foods are flat sour spoilage, TA spoilage, and putrefaction (explained below). Due to the interaction of food acid with the iron of the can, a fourth significant type of spoiling develops in a hydrogen expansion.

Types of Spoilage by Thermophilic Spore-forming Bacteria

Because their spores are more heat-resistant than those of most mesophilic bacteria, thermophilic bacteria are mostly responsible for the spoiling of commercially heat-processed canned foods caused by inadequate processing. Flat sour spoilage, TA spoiling, and sulphide spoilage, or “sulphide stinky,” are the three most common types of spoilage caused by thermophiles.

a. Flat Sour Spoilage

- This type of spoilage receives its name from the fact that the ends of the can of food remain flat during souring, or from the flat sour bacteria producing lactic acid in the food.

- Due to the typical appearance of the unopened can, this sort of spoilage cannot be recognised by visual inspection and must be discovered by cultural methods.

- Bacillus species are mostly responsible for the deterioration of low-acid foods such as peas and corn (group I) that fall within this category.

- B. coagulans is a particular thermophilic bacterium responsible for the flat sour rotting of acidic foods, such as tomatoes and tomato juice.

- Bacillus species capable of producing acid in the absence of gas may be mesophiles, facultative thermophiles, or obligate thermophiles.

- The spores of mesophiles are the least heat-resistant and are typically destroyed by heat processing; hence, flat sour rotting of low-acid foods is of little significance.

- The spores of thermophiles, on the other hand, are significantly more resistant to heat and can survive the heating process to generate flat sour rotting.

- Surviving thermophiles, such as B. stearothermophilus, would not cause deterioration unless the food was kept hot for a period of time, such as during slow cooling or tropical storage, whereas facultative thermophiles could grow at normal temperatures.

- Typically, plant equipment, such as blanchers, is the immediate source of flat sour bacteria, but they can also originate from sugar, starch, or soil.

- The ability of B. coagulans to develop in tomato juice is dependent on the amount of spores present, the oxygen content, and the juice’s pH.

- The organism, which is homofermentative in almost anaerobic conditions and heterofermentative in aerobic settings, may develop in environments with low oxygen concentrations.

b. TA Spoilage

- This type of spoilage is caused by a bacteria known as TA, which is an abbreviation for “thermophilic anaerobe not producing hydrogen sulphide” or Clostridium thermosaccharolyticum.

- This is a spore-forming thermophilic anaerobe that produces acid and gas in meals. The carbon dioxide and hydrogen gas may cause the can to rupture if it is exposed to high temperatures for an extended period of time.

- The stench of rotten food is typically sour or “cheesy.” Sources are identical to those of flat sour bacteria.

c. Sulfide, or “Sulfur Stinker,” Spoilage

- Desulfoto-maculum nigrificans is responsible for the deterioration of low-acid foods, such as peas and corn.

- This bacterium’s spores are significantly less resistant to heat than those of flat sour and TA bacteria; hence, their presence in canned foods indicates gross underprocessing.

- The organism is a thermophile and, as such, requires inadequate cooling of heat-treated foods or hot storage for its development.

- It is discovered by the black (FeS) colonies it produces in iron sulfite agar at 55 degrees Celsius. When a can of canned peas or corn is opened, the odour of hydrogen sulphide is obvious.

- In maize, there is a bluish-gray liquid in which black germs and grey kernels float.

- Peas typically emit an H2S odour without a noticeable discolouration. The origins of the spores are comparable to those of flat sour and TA bacteria, with the exception of manure.

Types of Spoilage by Mesophilic Spore-Forming Bacteria

Underprocessing causes the majority of spoilage by mesophilic microbes, which are spore-forming bacteria of the genera Bacillus and Clostridium. However, mildly cooked foods, such as some acidic ones, may allow the survival and deterioration of non-spore-forming bacteria, yeasts, and moulds.

a. Spoilage by Mesophilic Clostridium Species

- Sugar-fermenting Clostridium species, such as C. butyricum and C. pasteurianum, create the butyric acid type of fermentation in acid or medium-acid meals, causing the container to swell due to the production of carbon dioxide and hydrogen gas.

- Other species, including C. sporo-genes, C. putrefaciens, and C. botulinum, are proteolytic or putrefactive, degrading proteins and producing malodorous chemicals such hydrogen sulphide, mercaptans, ammonia, indole, and skatole.

- The can swells due to the production of carbon dioxide and hydrogen by the putrefactive anaerobes.

- The spores of some putrefactive anaerobes are highly resistant to heat; hence, putrefaction combines flat sour and TA deterioration as the most common types of biological spoilage of underprocessed canned foods.

- Because the spores of saccharolytic clostridia, also known as “butyrics,” have a relatively low heat resistance, spoilage by these anaerobes occurs most frequently in canned foods processed at 100 C or less, as well as in many commercially canned acid foods and home-canned foods processed using the hot-water, flowing-stream, or oven methods.

- C. pasteurianum has been discovered to contaminate acidic canned foods, such as pineapple, tomatoes, and pears.

- Such deterioration is more likely when the food’s pH is more than 4.5. Home-canned goods cooked to approximately 100 degrees Celsius may be damaged by saccharolytic bacteria, which produce butyric acid, carbon dioxide, and hydrogen.

- Putrefactive anaerobes thrive in low-acid canned foods, such as peas, corn, meats, fish, and chicken, but may occasionally contaminate other foods.

b. Spoilage by Mesophilic Bacillus Species

- The heat resistance of the spores of distinct Bacillus species varies widely, but in general, the spores of the mesophiles are less resistant than those of the thermohiles.

- The spores of the majority of mesophiles are killed quickly at 100 degrees Celsius or less, although a few species can survive the heat treatments used in steam-pressure processing.

- The spores that survive may not always lead to food spoiling because the circumstances in the can may not be conducive to germination and growth.

- Numerous Bacillus species are aerobic and hence cannot grow in a container with adequate ventilation. The food may be too acidic for the bacteria, or the environment may be otherwise hostile.

- However, there have been cases of B. subtilis, B. mesentericus, and other species growing in low-acid home-canned foods that were heated at 100 degrees Celsius.

- Bacillus species have damaged commercially canned foods, particularly in improperly evacuated cans.

- The majority of the spoilt foods have been fish and beef in cans, as well as evaporated milk. Aerobacilli, or gas-forming Bacillus species (B. polymyxa and B. macerans), have been observed to induce spoiling in canned peas, asparagus, spinach, peaches, and tomatoes, but it is uncertain whether these microorganisms survived the heat treatment.

- The container may have had a leak that allowed entry. The heat resistance of the spores of these bacteria is comparable to that of Clostridium pasteurianum.

Spoilage by Non-spore-forming Bacteria

- If viable non-spore-forming bacteria are discovered in canned foods, either a very weak heat treatment was performed or the germs entered the container via a leak.

- Some types of bacterial vegetative cells are reasonably resistant to heat in that they can withstand pasteurisation.

- These thermoduric bacteria include enterococci, Streptococcus thermophilus, some Micrococcus and Lactobacillus species, as well as Microbacterium*.

- Lactobacillus and Leuconostoc species that produce acid have been discovered growing on unprocessed tomato products, pears, and other fruits. The heterofermentative organisms may produce enough CO2 gas to cause the can to expand.

- Micrococci* have been found in meat pastes and similar products with very limited heat penetration, and S. faecalis or S. faecium are frequently found in canned hams that have only been partially sterilised and may be responsible for spoiling during storage.

- Typically, the presence of live non-spore-forming bacteria in heat-processed canned foods shows that the container has been compromised.

- Since cooling water is the most prevalent source of contamination, common bacteria in water are typically responsible for the deterioration of leaking cans. Some of these, such as coliform bacteria, create gas that causes the cans to expand.

- The tiny opening through which the bacteria enter appears to be clogged by a food particle, allowing gas pressure to build up in the can.

- Note that spore-forming bacteria can also enter a can through a leak, therefore aerobacilli (B. macerans and B. polymyxa) or clostridia could be responsible for the gas for mation.

- Frequently, non-gas-forming bacteria are observed growing in food in leaking cans alongside gas-forming bacteria or on their own.

- Obviously, it is conceivable for only one type of microbe to penetrate, resulting in an apparently pure culture.

- Pseudomonas, Alcaligenes, Micrococcus, Flavobacterium, Proteus, and others are genera of non-spore-forming, non-gas-forming bacteria that may enter.

- Less frequent nonsporeforming microorganisms besides those of water may enter the cans through leaks and cause deterioration.

Spoilage by Yeasts

- Since yeasts and their spores are rapidly eliminated by the majority of pasteurisation processes, their presence in canned foods indicates either gross underprocessing or leakage.

- Fermentative yeasts have damaged canned fruits, jams, jellies, fruit juices, syrups, and sweetened condensed milk, causing the cans to expand due to the CO2 created.

- Film yeasts may grow on the surface of jellied pickled pork, repackaged pickles or olives, and other similar goods, but their existence suggests recontamination, a lack of heat processing, and inadequate ventilation.

Spoilage by Molds

- Molds are likely the most prevalent cause of home-canned food spoiling; they enter the container through a leak in the seal.

- Mold can grow in jams, jellies, marmalades, and fruit butters with sugar concentrations as high as 70 percent and acidity levels typically found in these foods.

- It has been reported that adjusting the soluble extract of jam to 70 to 72 percent sugar in the presence of 0.8 to 1 percent acid can effectively eliminate the risk of mould growth.

- Aspergillus, Penicillium, and Citromyces strains found in jellies and candied fruits can grow in sugar concentrations as high as 67.5%.

- Acidification to pH 3 inhibited the growth of the first two moulds, and boiling the meal at 90 degrees Celsius for one minute eliminated all strains.

- Some moulds are fairly resistant to heat, particularly those that develop the densely packed mycelium masses known as sclerotia.

- Byssochlamys fulva, a pectin-fermenting mould, possesses ascospores that are resistant to heat processing and have caused the deterioration of bottled and canned fruits.

- This protective effect is enhanced if the sugar and fruit are introduced to the can separately, localising the sugar during processing.

Spoilage of Canned Foods of Different Acidities

- According to the preceding discussion, the classification of commercially canned goods by pH also classifies them according to the most likely kinds of deterioration.

- Thus, low-acid foods with a pH greater than 5.30 are particularly susceptible to flat sour spoilage and putrescence.

- Foods with a pH ranging between 5.30 and 4.50 are susceptible to TA deterioration. High-acid meals with a pH range of 4.5 to 3.7 are typically damaged by a flat sour bacterium or a saccharolytic anaerobe.

- High-acid foods with a pH below 3.7 often do not incur microbial deterioration, although in cans they may develop hydrogen swells (as may other high-acid foods).

Spoilage of Canned Meats and Fish

- Bacillus species cause softening and sourness in canned meats and fish, while Clostridium species (such as C sporogenes) cause putrid swelling.

- Less frequently, bacilli may create acid and gas and cause cans to swell. In several pastes, non-spore-forming agents have been discovered.

- In addition to deterioration by these organisms, which are predominantly spore formers that have survived the heat process, organisms entering through leaks may also cause spoilage.

- Insufficiently sterilised canned cured meats, such as ham or luncheon meats, may be subject to the production of carbon dioxide, nitrogen oxides, or nitrogen gas by Bacillus species (e.g., B. licheniformis, B. coagulans, B. cereus, or B. subtilis) from the nitrate, sugar, and meat, or to putrefaction with gas produced by Clostridium species.

- Such deterioration is typically prevented by proper refrigeration. Heterofermentative lactic acid bacteria (e.g., leuconostocs) may also create gas, but only after inadequate processing.

- Species of Bacillus and homofermentative lactic acid bacteria may be responsible for spoilage without gas production but with sourness and colour and texture alterations (e.g., Streptococcus faecium or faecalis).

Unusual Types of Spoilage of Canned Foods

- Certain types of food spoilage appear to be unique to one or two food types. Only peas and sweet corn have been documented to suffer from sulphide rotting.

- Bacillus betanigrificans* in the presence of a high concentration of soluble iron causes black beets.

- This differs from the darkening caused by a boron shortage in the soil. Bacillus species can cause milk in a can, cream, and evaporated milk to become sour, acidic, and curdled.

- The only significant alkaline canned vegetable, hominy (pH 6.8 to 7.8), passes through a flat sour deterioration with a sweet flavour.

- Because the spores of saccharolytic clostridia are less resistant to heat, putrefactive clostridia are more likely to ruin canned poultry than saccharolytic clostridia.

- It is possible for canned sweetened condensed milk to become gassy as a result of the growth of yeasts or coliform bacteria, to get thickened by a Micrococcus* species, or to exhibit buttons, which are minute masses of mould mycelium and coagulated milk typically found on the surface of the milk.

- The size of the buttons is constrained by the amount of free oxygen in the can’s headspace.

- Sometimes, as a result of auto-sterilization, there are no living organisms present in visibly biologically spoiled food cans.

- All vegetative cells have died, including non-sporulating spore-forming cells.

Spoilage in Cans Food

To conclude that the canned food is not spoiled, both the can’s exterior and the contents must be in good condition. There are numerous causes of can spoilage, which can be categorised as follows: 1. natural causes 2. Chemical effects 3. Microbial causes

1. Physical damage

- If food cans are handled carelessly when being lifted, moved, loaded into baskets for retorting, or packaged into boxes, they are prone to sustain damage.

- The can loses its visual appeal.

- Depending on the size of the dents, the food within the can may not be damaged.

- If the dent is on or near the double seam, the seam may become loose, resulting in leaking.

- In addition to causing physical damage, a sudden spike or reduction in retort pressure can cause panelling.

- Additionally, panelling may arise because to the too large head space.

- The second reason is the overpacking of food, as there is no room for expansion of the contents of the can during retorting.

- This could result in flipper or springer-style rotting.

- Moreover, overpacking leads to insufficient processing, and surviving bacteria can proliferate within the can and cause it to spoil (bulging).

2. Chemical causes

- The most significant chemical cause of rotting is the reaction between the food and the can components (tin, iron).

- This reaction produces hydrogen gas and metal ions, resulting in an increase in the metal content of the product.

- The food within the can may still be edible when hydrogen gas is created, but consumers may not accept it.

- Additionally, excessive heat processing results in a non-enzymatic browning response that causes brown discoloration and charring.

3. Microbial causes

- During pre-processing, i.e., during the preparation of raw materials or after packaging but prior to retorting, the bacteria present in food may cause some spoilage.

- Despite the fact that heat processing eliminates microorganisms, food quality can be enhanced.

- If the level of rotting is minimal, it goes unnoticed; if it is significant, it is referred to as pre-process spoilage.

- In pre-process spoiling, the pH changes, gases are created, and the food softens.

- If there is a power outage or for any other reason, half-completed cans, filled and sealed cans held for an extended period of time prior to heat processing become spoiled.

- Such cans may feature a flipper or springer.

- It may not result in rough seas.

- Such cans may not contain living microbes or their spores. However, microscopy reveals more dead cells.

- The food within may not be of high quality.

- This sort of spoiling can be reduced by minimising delay in each stage and between stages, as well as by adopting appropriate hygiene and sanitation procedures.

Under-processing Spoilage

Several of the enumerated causes are liable for underprocessing.

- Thermal treatment insufficient to eliminate the most serious bacteria.

- Contamination by a highly resistant to heat microorganism not normally found in the food.

- Abnormally high level of contamination by typical contaminants.

- Erroneous retort operation.

- Instruments attached to the retorts performing improperly.

- There is air inside the retort due to insufficient venting.

- Changes in consistence, inappropriate filling in relation to increasing solids weight, solid-to-liquid ratio, head space, etc.

- The product’s initial temperature is low.

Post-processing spoilage

- Post-processing spoiling is another microbiological deterioration.

- Despite adequate preparation, processing, and can chilling, heat-processed cans may occasionally deteriorate due to the introduction of microbes. Leaking cans are the only cause of this type of deterioration.

- This deterioration is due to a loose double seam and physical damage to the double seam.

- As water is sucked into the can during chilling, bacteria in the water contaminate the food.

- Sometimes, leaking cans are positioned close together, and the cans bulge due to the gases created within.

- This type of spoiling is known as “leaker spoilage.”

- In such cans, a mixture of non-spore forming and spore forming microorganisms are present.

- This deterioration can be reduced by adding 4–7 ppm of free chlorine to the can cooling water.

- This deterioration is significantly less with air cooling than with water cooling.

Other causes of spoilage

- Rusting of cans is a significant cause of significant losses in the canning business.

- The rusting of cans is caused by storage under humid climatic conditions, salty breeze, corrosive gases, and fluctuating storage temperatures.

- Among the causes of rust include careless handling of cans, corroded trolleys, heavy embossing of can ends for coding, and overcooling of cans.

- Corrosive label pastes or adhesives.

- Poor warehouse conditions (dust, storing on the floor, leakage from top layer of cans etc).

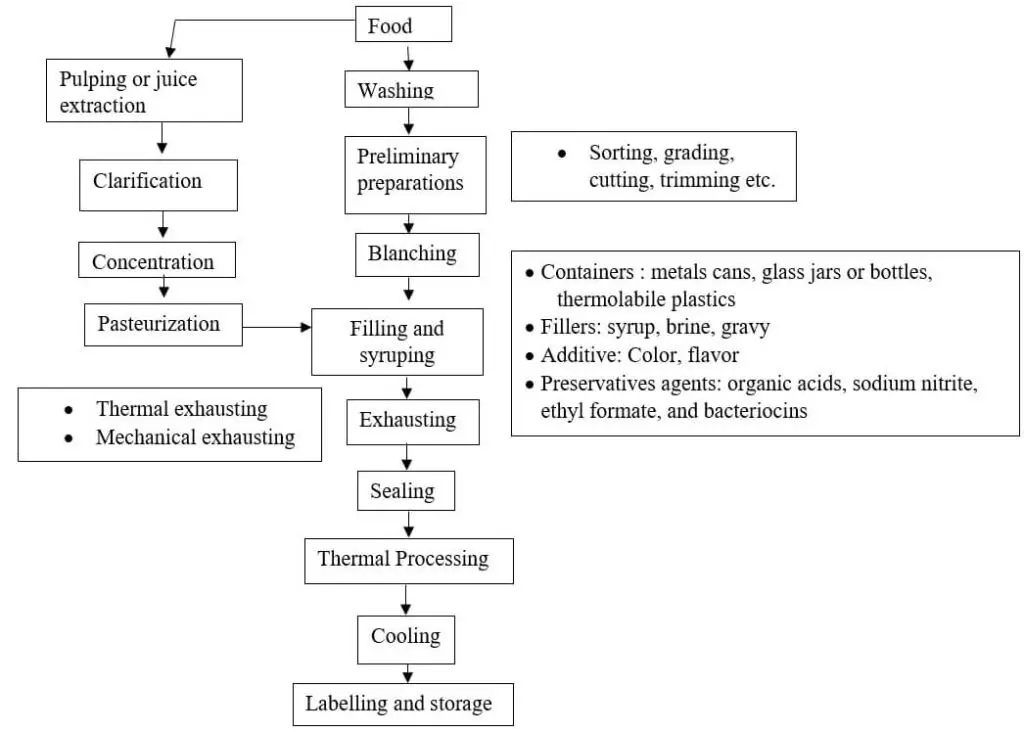

What Is Canning?

Canning is a process for preserving food in jars at high temperatures for an extended length of time, which kills microorganisms and deactivates enzymes that cause food to decay. As the food cools, the heating process forces air out of the jar, establishing a vacuum seal.

Essentially, heating filled, airtight jars causes the contents to expand and release steam, forcing air out of the jars. It produces a vacuum seal on the jar once it has cooled. The sugar content and acidity might effect canning and shelf life, so it’s recommended to follow a canning recipe when starting out to determine which method is ideal for the product you will be canning.

Canning Steps or Process

1. Preparations

- The containers that will be filled with food are preheated for sterilisation.

- The preparation of different sorts of food varies. According to their types, food preparation encompasses washing, trimming, sorting, grading, peeling, cutting, dicing, slicing, segmenting, pitting, and blanching.

2. Filling in the containers

- The prepared food is then placed in the sterilised containers.

- The cans are then filled with hot sugar syrup or fruit juice solutions, brine with spices for vegetables, and gravy for meats.

- This technique aids in the addition of flavouring and preservatives, further sterilisation, and the removal of air.

3. Exhausting

- Exhausting refers to the process of expelling air from the can prior to sealing.

- Exhausting aids in preventing excessive pressure and staining during the sterilisation process.

- Primarily, it prevents cans from bulging and inhibits the chemical interaction that occurs between containers and food.

4. Sealing

- After the can has been consumed, it is immediately sealed.

- There are several forms of sealing based on the product, such as screw type or crown capping machines for sealing glass jars and bottles, and dielectric or conduction heating for sealing plastic pouches.

- During canning, the temperature must not go below 74 degrees Celsius.

5. Processing of the can

- The cans are heat-treated at the appropriate time and temperature immediately after sealing.

- The primary objective of can processing is to eradicate microbes and their spores without compromising the nutritional value of the food.

- The applied heat is typically above 100 °C (vegetative bacteria are killed at 80 °C/30 minutes, spore-forming microorganisms at 110 °C/30 minutes, and spores at 121 °C/3 minutes).

6. Container cooling

- The cans are swiftly chilled to room temperature after manufacturing.

- Either soaking the heated cans in cold water or blasting them with jets of cold water is used.

7. Labeling and storage

- After cooling, the outer surface of the cans is dried for labelling.

- The label should include product identification, the brand name, the net content by weight or volume, a code number, the name and address of the manufacturer, a list of ingredients, nutritional information, the date of manufacture, and the date of expiration.

- After labelling, the cans are stored in cool, dry locations prior to shipment.

References

- Vergara-Balderas, F. T. (2016). Canning: Process of Canning. Encyclopedia of Food and Health, 628–632. doi:10.1016/b978-0-12-384947-2.00110-0

- Pither, R. J. (2003). CANNING | Quality Changes During Canning. Encyclopedia of Food Sciences and Nutrition, 845–851. doi:10.1016/b0-12-227055-x/00163-2

- Abdulhay, H. S. (2016). Detection of Microbial and Chemical Contamination in Canned Meat Available in Baghdad Local Markets. (May 2015).

- Evancho, G. M., Tortorelli, S., & Scott, V. N. (2009). Compendium of the Microbiological Spoilage of Foods and Beverages. In Compendium of the Microbiological Spoilage of Foods and Beverages. https://doi.org/10.1007/978-1-4419-0826-1

- Featherstone, S. (2015). Spoilage of canned foods. A Complete Course in Canning and Related Processes, 27–42. https://doi.org/10.1016/b978-0-85709-678-4.00002-6

- Food Microbiology, William C. Frazier; Fourth Edition.pdf. (1995).

- Jay, J. M. (2000). Modern food microbiology Sixth edition.

- Kempe, L. L., Graikoski, J. T., & Bonventre, P. F. (1958). Combined Irradiation-Heat Processing of Canned Foods II. J. Infectious Diseases, 124, 295–300. Retrieved from http://aem.asm.org/

- Kharel G.P., H. F. (2010). food preservation. Principle of Food Preservation, 466.

- Kumar, A. (2019). Food Preservation: Traditional and Modern Techniques. https://doi.org/10.31080/ASNH.2019.03.0529

- Lin, C.-C., Wu, B.-K., & Lin, D.-K. (1968). Spoilage Bacteria in Canned Foods I. Flat Sour Spoilage Bacteria in Canned Asparagus and the Thermal Death Time Downloaded from. In APPLIED MICROBIOLOGY. Retrieved from http://aem.asm.org/http://aem.asm.org/http://aem.asm.org/

- http://epgp.inflibnet.ac.in/epgpdata/uploads/epgp_content/food_technology/technology_of_fruits_and_vegetables/17.spoilage_of_canned_fruits_and__vegetables/et/2848_et_m17.pdf

- https://www.coursehero.com/file/34298941/spoilage-of-canned-fooddocx/

- https://www.basu.org.in/wp-content/uploads/2020/04/7th-PPT-of-Foods-and-Industrial-MicrobiologyCourse-No.-DTM-321.pdf

- https://www.indiabix.com/microbiology/heated-canned-foods/

- https://www.biologydiscussion.com/foods/spoilage-of-canned-foods-with-diagram-microbiology/59052

- https://www.fda.gov/food/laboratory-methods-food/bam-chapter-21a-examination-canned-foods

- https://www.biologydiscussion.com/food-microbiology/spoilage-of-non-canned-and-canned-foods/55709

- https://faculty.weber.edu/coberg/class/3853/3853%20Canned%20Foods%20Handout.htm

- https://gcwgandhinagar.com/econtent/document/1587965419microbiology-of-canned-foods.pdf

- https://www.fsis.usda.gov/sites/default/files/media_file/2022-02/22-Investigation-of-Canned-Food-Spoilage-Incidents.pdf

- https://extension.umn.edu/preserving-and-preparing/storing-canned-food

- https://microbenotes.com/spoilage-canned-foods-preservations/

- https://www.rpcau.ac.in/wp-content/uploads/2020/03/Changes-in-canned-foods-and-spoilage.pdf

- https://www.onlinebiologynotes.com/microbiological-spoilage-of-canned-foods/

- http://ecoursesonline.iasri.res.in/mod/page/view.php?id=5128